CECAMASA committed to milling machines "made in Spain"

As many of you may already know, milling machines feature prominently in our wide selection of used machinery. Currently all of our second-hand milling machines available for sale are taken over by Spanish brands. In CECAMASA are committed to manufacturers of milling machines "made in Spain” as exponents of high quality machinery, great performance and high precision. Next, we are going to talk about these manufacturers who, with their good work, have crossed borders and have made a name for themselves internationally.

ZAYER milling machines

Zayer, based in Vitoria-Gasteiz (Basque Country), it defines itself as a machine tool company with an “entrepreneurial spirit and innovative capacity”. Not surprisingly, Zayer has more than 60 years of experience designing and manufacturing milling machines (bed type milling machines, bridge milling machines, gantry milling machines, moving column milling machines) and machining centers. In addition to having a long history in the market, ZAYER has a wide commercial network that includes its own offices in countries such as Italy, Brazil and China. They can also boast a highly qualified technical assistance service that operates in more than 40 countries.

At CECAMASA we are proud to have a ZAYER bed type milling machine, a ZAYER mobile column milling machine and a bridge milling machine from the same brand. In our post “Wide selection of bed type milling machines in CECAMASA" you will find detailed information about our ZAYER 30KF-5000 bed type milling machine.

On the other hand, we have a ZAYER 30 KCU 16000 AR a mobile column milling machine, a top model from this manufacturer. That machine is in excellent mechanical condition. Its generous 16,000 mm longitudinal, 1,500 mm transverse and 3,500 mm vertical travels, make this milling machine an ideal machine for machining heavy and large parts. Therefore, we speak of a robust, reliable and precise machine. Also, we would like to highlight of this the mobile column milling machine, the chip conveyor, the internal cooling, the operator's cabin with elevation and the numerical control HEIDENHAIN iTNC 530.

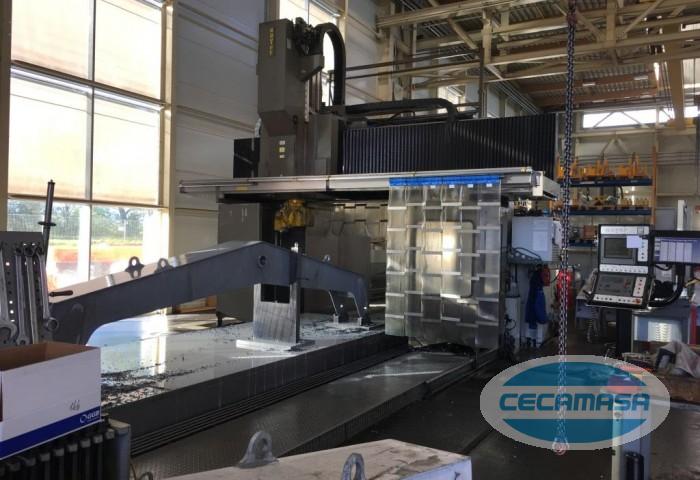

If you want to know more about this machine, we encourage you to consult its technical data sheet where you will find detailed all its specifications. Finally, we have a ZAYER KCPU 6000 AR DT bridge type with double table system. It is a very versatile milling machine and highly recommended for the heavy tooling sector and for structures. We also encourage you to consult its technical data sheet so that you can get an idea of all the benefits it can offer.

SORALUCE milling machines

Soraluce is another of the great Spanish machine tool manufacturers. Based in Bergara (Basque Country), Soraluce is part of the DANOBATGROUP business group, one of the most important in all of Europe. With an experience of more than 50 years in the market, its success, according to its website, is based on "excellent quality, star service and cutting-edge technology." SORALUCE reveals itself as a leading company in milling, boring and turning technology with an international projection. Its business strategy is based on 4 pillars: development of leading technology, commitment to the digitization of the company, highly qualified service and the aspiration to manufacture less polluting machines.

Nowadays, in CECAMASA we have three bed type milling machines of the brand SORALUCE: Soraluce TA-35, Soraluce TA A-20 and SORALUCE TA-20. In our post “Wide selection of bed type milling machines in CECAMASA" you will find detailed information about our Soraluce TA-35 bed type milling machine. Regarding the SORALUCE TA-20 milling machine, although among the three SORALUCE series, the TA series is the lightest, this does not mean that it is the worst machine. In fact, this bed type milling machine provides a high speed of axis translation with linear guide and is in a geometry of 0.02. It also has a full enclosure, has a chip conveyor and it is equipped with HEIDENHAIN control. Finally, our SORALUCE TA A-20 milling machine apart from having a full enclosure, chip conveyor, HEIDENHIAN control, it is as well equipped with a tool changer of 20 units.

NICOLAS CORREA milling machines

The company NICOLAS CORREA SA, based in Burgos, it was founded in 1947 and is dedicated to the design and manufacture of medium and large size milling machines. On their website they highlight that both the design and manufacture of their machines are carried out entirely in Europe. They have a commercial network, as well as a technical service, at an international level. Aware of the growing concern for environmental issues, NICOLAS CORREA has the ISO 14001 Certificate for Environmental Management. This certification accredits quality standards and respect for the environment.

Today at the premises of CECAMASA we have a Nicolas Correa bed type milling machine: the Nicolas Correa A30/40 milling machine, which has an automatic head and a central support in the table with T-slots. That support allows to fix pieces at the table side.

Moreover, we have a NICOLAS CORREA FP-30/40 bridge milling machine. The FP series is one of the best-sellers of this manufacturer. This bridge milling machine can work with two heads: the direct output head (6,000 rpm) and a 360º manual HURON head (3,000 rpm). It is equipped with a HEIDENHAIN 426 numerical control.

LAGUN milling machines

LAGUN MACHINE TOOLS, S.L. is another manufacturer of bed type milling machines and mobile column milling machines based in the Basque Country, specifically in Azkoitia. This Basque company has been manufacturing milling machines for more than 60 years. As stated on their website, their business strategy is based on focusing on "the design and manufacture of medium-sized milling machines, at a competitive price and proven reliability." One fact to highlight is that they allocate more than 10% of their staff to the R + D + I department. Their main market is Europe, with Germany topping the list, although they also export to markets such as India, Turkey, the US and Canada. With a broad export vocation, LAGUN has a qualified technical service to respond to its international customers.

Currently, at CECAMASA we have two LAGUN bed type milling machines, both belong to the GBR3 model, the only difference between them is their year of manufacture, one dates from 2011 and the other from 2013. Both LAGUN GBR3 milling machines they are equipped with HEIDENHAIN iTNC-530 control, have through-shaft cooling and a chip conveyor. Likewise, it should be noted that they are equipped with an automatic 2.5º-2.5º head that reaches 3,000 rpm.

More information

We hope this post has aroused your interest and you want to know more about our milling machines "made in Spain". If so, do not hesitate to contact us through our email address cecamasa@cecamasa.com or by calling us at +34 935 730 225. Our team of sales representatives and technicians will answer all your questions.

CECAMASA closes the sale of a plate bending machine in South America

The team of CECAMASA comes back to work after summer holidays. In CECAMASA we finished the month of July by closing the sale of a SERTOM-CASANOVAS 4-roll hydraulic bending machine with a client from South America. In fact, during these weeks of August the plate bender has traveled overseas in container to its destination. It is a large used plate bender with a maximum bending length of 3050 mm and a bending capacity of 50 mm. A machine equipped with control for the benders, hydraulic L-rafter and lateral supports.

The logistics process which involves the shipping of this machine or any other machine of a certain size is not easy. And if this machine is shipped abroad there are additional risks as the journey is longer. That is why it is vital to know how to carry out the loading, in that way, during the manipulation of the machine, it will not not suffer any damage and to guarantee that it willl arrive safe and sound at destination.

Our team of technicians has a vast experience in this field and they care along the whole process by taking all the necessary precautions. For this purpose they carry out a study of the machine to be immobilized. Many aspects have to be taken into account: from the dimensions and weight of the load, the type of transport tha is going to be used, mooring angles, the friction factors and so on. Nothing can be left to chance. The machine must be supported using the means or elements that are necessary to prevent and avoid blows, displacements, friction, etc. In the specific case of the above-mentioned bending machine, the biggest challenge its load presented was due to the weight of 52 tons of the body of the machine.It was necessary to use a special Mafi team for its transport.

Find below a few photos of the loading process of the above-mentioned bending machine. In that way, you will see for yourselves, the great job made by our mechanics:

CECAMASA: vast experience in exporting machines

Although in CECAMASA we have a large portfolio of domestic clients, we do not neglect the international sphere either. We have sold machining centers to clients in Argentina, moving column milling machines to Mexico, cnc lathes with inclined bed to Turkey, and thus a long list of machines and countries. Experience that supports us and that speaks for itself. Despite the difficult times we are going through, we are delighted to see that companies around the world are struggling to get ahead. And it is that adversity manages to bring out our most creative side. There is a Galician saying that says that need teaches more than university and perhaps popular wisdom is right again. So we are especially proud of this latest sale of a bending machine to South America in such current difficult times.

CECAMASA: balance of the first semester of 2020

The effects of the COVID-19 pandemic especially suffered during this second trimester of this turbulent 2020 have meant without any kind of doubt a setback in the economic activity of the companies. Unfortunately CECAMASA has not been an exception. However, after implementing the due security protocols stablised by regulations, our team of mechanics has not been interrupted its daily work in the workshop. It was necessary to meet the deadlines of the orders comitted before the lockdown. And now we are in the called "new normality", the statistics of the sector are not very optimistic. In fact, the president of the AFMEC (the Spanish Association of Contract Manufacturing and Mechanical Engineering), Mr Alberto Perez outlines for an interview made by Metal Industry that according to his estimates: "commercial activity in the national market is 65% of normal and in the international market is 40%." In CECAMASA we trust that the sector, despite the current situation, will be able to reverse the damage suffered and return to a more optimistic scenario.

In this sense, CECAMASA has proposed to help the business fabric and the self-employed by making available capital equipment renting financing. In this way, we intend to contribute our grain of sand so that business projects are not paralyzed for a purely economic issue. We recommend that you read our July post "Machinery renting, an attractive alternative to buying” to learn more about this topic.

More information

We remind you that in CECAMASA we have a large inventory of second-hand machinery. The milling machine (either in its mode of bed type milling machine , bridge milling machine, traveling column milling machine), the vertical machining centre and the cnc lathe are the star machines in our inventory. Not in vain we are specialists in these families of machines, although we have shears, folding machines, presses, saws, drills, grinding machines and a long list of used machines with excellent performance. If you want more information, do not hesitate to contact us. Write us an email at cecamasa@cecamasa.com or call us at +34 935 730 225 and our team will answer all your questions.

Machinery renting, an attractive alternative to buying

What is renting?

The purchase of a machine can often involve a significant financial outlay that detracts liquidity and resources from the company or freelance who carries out the operation. That makes one think about it very well before taking the step of materializing an investment in capital goods. Making an investment of a certain amount can make it impossible to allocate resources to other important aspects of the business. But today, buying is not the only way to acquire and enjoy the benefits provided by machinery. This is when concepts like "renting” are emerging as attractive alternatives to traditional purchasing of capital goods.

The machinery renting makes it easier for companies and freelancers to use capital equipment without having to make a large investment. The economipedia defines renting as "a rental agreement for a movable asset in which one of the parties (the lessor) agrees to transfer said movable asset in exchange for the other party (the lessee) paying a periodic fee". The capital goods renting covers a wide spectrum of machines: from industrial machinery such as milling machines, machining centers or lathes to electrical machinery, robotics, etc.

Advantages of Renting

Renting has many advantatges. Firstly, it is not necessary to make a big outlay at the beginning of the operation. In fact, the payment is divided into convenient monthly, biannual or annual installments according to the lessee's financial needs. In the case of renting, the machine is not included on the balance sheet either on the CIRBE (Bank of Spain Credit Reporting Agency), that is why it does not increase the debt ratios of the company. Moreover, as the payment plan is stated for an agreed period of time, there is an absolute control on how much is going to be paid in every moment. In that sense, we would like to point out the fact that variable costs such as the insurance, maintenance,etc are non-existent. Another incentive to chose the renting option is that the installsments are regarded as an expense, therefore, they are tax-deductible.

CECAMASA offers you renting financing

In CECAMASA we want to make things easy for you. Aware of the difficult times we are going through, we do not want you to give up your projects for a purely monetary issue. So if your project requires acquiring or renovating a machine, we offer you a wide selection of machinery and we offer you clear and agile financial solutions. As you may already know, our extensive machinery park includes milling machines (bed type milling machines, traveling column milling machines, bridge type milling machines), cnc lathes, machining centers and many other machines in the metallurgical sector (shears, pressbrakes, grinders, presses, saws, etc). In our inventory there is no shortage of brands such as Zayer, Soraluce, Nicolas Correa, Geminis, Doosan, Daewoo, Lagun, Juaristi and a long etcetera of other prestigious brands, both national and international.

If this post has managed to arouse your interest and you want to know everything that CECAMASA can offer you, do not hesitate, and contact us. Drop us an email at cecamasa@cecamasa.com or call us at +34 935 730 225.

Wide selection of bed type milling machines in CECAMASA

What is a bed type milling machine?

The Institute of Educational Technologies (ITE) defines bed type milling machine as a machine for machining by chip removal which can perform any kind of machining. Its main parts are: fixed bed, arm, upright or motorised bridge and table.

In the case of the bed type milling machine, the head moves up and down along the column. The table, however, only moves along the bed in its entire width.

In CECAMASA we have a wide selection of second hand bed type milling machines equipped with numercial control (cnc). Our inventory has prestigious brands such as ZAYER, SORALUCE, NICOLAS CORREA, LAGUN or ANAYAK.We are going to talk in further detail about the three bed type milling machines of our second-hand stock wich are in the state of immediate delivery.

Second-hand ZAYER 30 KF-5000 milling machine

In CECAMASA were experts in the brand Zayer. Zayer is a company based in Vitoria-Gasteiz with a long proven track record in the field of the machine tool of high performance. Zayer manufactures bed type milling machines, travelling column milling machines, gantry milling machines and milling centers. Zayer defines itself as "a company which guarantees machining solutions of high added value, technological and high quality".

Currently, we have in stock a ZAYER 30KF-5000 bed type milling machine. CECAMASA has carried out a thorough overhauling of that machine. Our team of highly qualified technicians has checked all the mechanic and electronic parts of this milling machine. They also have polised the covers, have replaced the polycarbonates and painted the machine.

The travels of this bed type milling machine are 4710 mm in the X-axis, 2013 mm in vertical and 1508 mm in cross. This exceptional machine presents a numerical control HEIDENHAIN TNC-426. It has an automatic head of 45 degrees with 0.001 positioning with twist of the two bodies simultaneously along with the spindle. The spindle reaches 3,000 rpm. In spite of being a bed type milling machine, it presents travels of a travelling column, but it does not require the foundation of a travelling column milling machine. Moreover, it has a chip conveyor. Find below a video where you can see the machine working under power:

Used SORALUCE TA-35 bed type milling machine

Along with Zayer, Soraluce is another leading brand in technology of milling. That comes as no surprise as Soraluce is part of one of the most relevant business group of machine tool in Europe: Danobatgroup. The Soraluce milling machines stand out for its realibility and high performance. It is a company wich works hard for being always at tech avant-garde and owns several patents which endorse its spirit of innovation.

Right now we have three Soraluce milling machines in our inventory: a Soraluce TA-20 bed type milling machine, a Soraluce TA-A20 bed type milling machine and one Soraluce TA-35 bed type milling machine. Although you can find detailed information about all of them in our website, in this occasion we would like to focus on the Soraluce TA-35 milling machine.

It is a bed type milling machine from 2009, which presents a longitudinal travel of 3500 mm, a cross travel of 1200 mm and a vertical one of 1250 mm. It has an automatic head of 2,5-2,5 degrees and the spindle reaches 3,000 rpm. It is a second-hand milling machine with some very attractive extras: tool changer of 20 units, internal and external coolant supply, 2 chip conveyors, paper filter, full enclosure and electronic hand-wheel, model Heidenhain HR 410. Find below a video of the machine and you will see for yourselves its capacities:

Used Nicolas Correa A30/40 bed type milling machine

In today's post apart from talking about Zayer and Soraluce, we cannot forget Nicolas Correa. Another great manufacturer of milling machines, which designs and produce entirely its machines in Spain. Nicolas Correa Sa company has been listed on the Madrid Stock Exchange for over 30 years and it has a wide commercial network and technical service at international level.

Currently we have at CECAMASA's premises a Nicolas Correa milling machine: the Nicolas Correa A30/40 milling machine, of which we are going to go through now.

We will begin by telling you that the series A30 of the brand NICOLAS CORREA is characterised by being a very robust and reliable machine. The A30/40 model presents 4000 mm of X-axis travel, 1500 mm Z-axis travel and 1250 in Y-axis travel. Those travels make this second hand milling machine ideal for sectors such as the one of the casting, the sector of metallic structures, machine shops and machining in general.

The bed type milling machine CORREA A30/40 has an automatic head and a central support in the table with T-slots. This support allows staking pieces in the side of the table without taking up space in the work table.

Our team of mechanics has pre-tensed the spindles, checked the proper functioning of the automatic head in the two bodies, checked the lubrication system, adjusted wedges to the fall of the ram, revised the guidelines, polished the telescopic covers and painted the machine.

More information

In this post we have talked about three models of bed type milling machines, but the stock of CECAMASA is much wider. We invite you to visit our website and know all our models of second-hand bed type milling machines available for sale. And if you want to know more about those second-hand machines, please do not hesitate to contact us. Drop us an email at cecamasa@cecamasa.com or call us on +34 935 730 225 and we will inform you in further detail.

LAGUN machining centers for sale at CECAMASA

Within the wide selection of used machinery CECAMASA, machining centers are always present. Along with milling machines - whether they are bed type milling machines, bridge milling machines or traveling column milling machines - and the numerical control lathes, the machining centers have a prominent position in our machine inventory. In today's post we are going to talk about the machining centers of the LAGUN brand. The word LAGUNmeans "friend" in Basque. Honoring this name, the machining centers of this Basque brand are emerging as the best ally to the machining processes of any company. Not in vain LAGUN machining centers are characterized by their great rigidity and by their compact as well as their ergonomic design.

The company LAGUN MACHINERY SL as such was established in 2005 in Vitoria (Álava). However, its origins go back to 1928 when at that time it was called "LADISLAO ARAMBURU". Almost a century of dedication to the design of machines for sectors such as aeronautics, the automotive sector, the die-cutting sector, just to name a few. Currently, the company LAGUN MACHINERY SL is part of the MAHER HOLDING group, a conglomerate of companies focused on the world of machine-tool which has set itself the main objective of offering simple solutions for an increasingly complex and demanding market.

CECAMASA has in its facilities located in the municipality of Parets del Vallès (Barcelona) two second-hand LAGUN L-1000 machining centers, which we will talk about below, as well as an L-1600 machining center (new machine) on display at the showroom.

Used LAGUN L-1000 vertical machining center (Year 2014)

This LAGUN L-1000 machining center is a modern machine, manufactured specifically in 2014, which is in excellent condition. The dimensions of the work table are 1070 × 510 mm and the maximum allowed weight are 700 kilos. Its travels are 1030 mm on the X axis, 530 mm on the Y axis and 540 mm on the Z axis. It also has a numerical control HEIDENHAIN iTNC 530 and it is equipped with a RANDOM 24-tool charger, chip conveyor and SCHENEIDER climate control equipment in the electrical cabinet. It is also prepared for a fourth axis. This second-hand machine stands out for its robustness and, above all, for its agility in axle translation, reaching 8,000 rpm. But as an image is worth a thousand words, we leave you with a video of the machine under power so that you can see for yourself the capabilities of this machining center:

Used LAGUN L-1000 Vertical machining center (Year 2011)

Convinced of the good results offered by this brand, in CECAMASA we have in inventory another LAGUN L-1000 vertical machining center. In this case it is a machine which dates from 2011 and with the same technical specifications described in the previous section. Then we also leave you with a video of the machine that is hosted in our YouTube channel, which I encourage you to subscribe to keep up to date with our news on used machinery.

LAGUN L-1600 machining center on display in our showroom (new machine)

If instead of second-hand machinery, you decide to invest in a new machine and you are looking for a larger machining center, you cannot miss the LAGUN L-1600 machining center that we have on display at the showroom of CECAMASA. In our post titled "CECAMASA exhibits a LAGUN L-1600 machining center in its facilities" you will find all the information related to this option. Emphasize that this is a machining center equipped with the latest version of numerical control from the prestigious brand HEIDENHAIN, the HEIDENHAIN TNC-640, and whose spindle reaches a speed of 8,000 rpm in its standard version, although the customer can choose to increase that speed to 10,000, 12,000 or even 15,000 rpm depending on their production needs. In fact, the model exhibited in the CECAMASA showroom reaches 10,000 rpm.

More information

If you want more details about these LAGUN machining centers, write us an email at cecamasa@cecamasa.com or call us at +34 935 730 225 and we will inform you in detail. If this pandemic has taken its toll on you economically, don't worry. At CECAMASA we can put you in contact with financing experts who will propose financial solutions adapted to your needs.

CECAMASA: precision cnc lathes at adjusted prices

According to the latest statistics released by the IMF, it is expected that Spain alongside Italy, will be the most economically affected country by the pandemic. Specifically it is estimated for our country 12.8 percentatge points below of the GDP. Without any kind of doubt bad news for the business fabric and, in general, for the whole Spanish society. In spite of this not encouraging picture, there is still hope as the same IMF predicts a growth of 6.3 percentatge points in 2021. Thanks to these data in CECAMASA we are optimistic about the future, although it will not be easy. In that context of uncertainty, it is necessary more than ever to come up with witty and creative new projects which allow us to move on. From CECAMASA we would like to contribute to the economic recovery by offering to our customers secondhand machines at adjusted prices. In that sense, in this post we are going to talk about our range of lathes with numerical control. First, we are going to focus on the promotion that we are going to launch this month of a second-hand TRAVIS TR-1 cnc lathe and afterwards we will talk about a GEMINIS GHT5 G2 1000×4000 cnc lathe of high performance and, finally, a DOOSAN PUMA 240M cnc lathe which, although more modest in dimensions and capacities, is shaping up to be a great machine.

Promotion of the month: TRAVIS TR-1 cnc lathe

The TRAVIS TR-1 cnc lathe reveals like the star of this month of July, having been selected by CECAMASA as the offer of this summer. We are talking about a cnc lathe in perfect operational conditions. it is a second-hand cnc lathe of semi-control with a distance between centers of 1000 mm and swing over bed of 450 mm. This cnc lathe is well-equipped: it has three universal chucks, several sets of jaws, a quick-change manual turret with 3 tool-holders, a quick-change manuel turret with 5 tool-holders and two steady rests, one (open and another one closed). If you want to know more about this lathe, call us at +34 935 730 225 or drop us an email to cecamasa@cecamasa.com and book an appointment to see it under power at our facilities in Parets del Vallès (Barcelona).

GEMINIS GHT5 G2 1000 × 4000 cnc lathe: a high-performance lathe

In our post from last March 13thwe were talking about our weakness for the GEMINIS brand of cnc lathes. Lathes manufactured by GEMINIS LATHES SA, a leading company based in the Basque Country that stands out for the production of large horizontal lathes for heavy machining. In that same post we announced that we had acquired a GEMINIS cnc lathe model GHT5 G2 with a distance between centers of 4000 mm and a swing over bed of 1000 mm. It is a second-hand lathe equipped with a FAGOR numerical control. Among its extras, we would like to outline its support for boring, its TdG chuck of 4 independent jaws and 900 mm diameter, its automatic SAUTER turrent of 4 stations with 290 mm diameter, automatic lubrication and chip conveyor. Moreover, it has a 430 mm diameter steady rest, several points, several jaws, boring bars, etc. An excellent machine, ideal for machining pieces from the automotive, railway, aeronautics and energetic sectors.

DOOSAN PUMA 240M cnc lathe: economic lathe that offers excellent results

In our wide used machinery stockwe also have a DOOSAN cnc lathe, a highly prestigious Korean brand with a long presence in the market. In fact, Doosan Infracore Machine Tools was established in 1976 in the city of Changwon (Korea), appears on the internationl market in 1981. Doosan struggles constantly to make for itself a name among the top brands of the market and it has gained a great reputation as manufactuerers of machines of excellent quality-price ratio. Our second-hand DOOSAN PUMA 240M has a max machining length of 513 mm and a swing over bed of 550 mm. This second-hand lathe is equipped with a FANUC numerical control and it has a long list of accessories, such as: a hydraulic HIDRAM chuck of 4 jaws with 210 mm diameter, a live tool turret of 12 stations, tool pre-setter, 4 tool-holders, one motorised turning angular tool-holder, one motorised turning facing tool-holder, tailstock with hydraulic clamping, chip conveyor and part catcher. It is an excellent production lathe to produce series of pieces of small dimensions.

More information

If you want to know more about these or other machines from our wide selection of used metallurgical machinery, contact us. Our sales and technical team will be happy to advise you and put all their experience at your disposal. More than 30 years in the market guarantee our know-how and professionalism. We can also help you contact experts who will advise you in the best possible way to find the financial solution that best fits your budget.

CECAMASA completes the assembly of two bridge milling machines at its facilities

Despite the adverse circumstances caused by the COVID-19 pandemic, CECAMASA has not ceased its activity. Adhering to strict security protocols to avoid contagions, our operators have continued to work on the checking, overhauling and commissioning of our machines. As a result of all this effort, our team of highly qualified technicians has assembled two bridge milling machines at our facilities located in the municipality of Parets del Vallès (Barcelona) for a showroom. It is a NICOLAS CORREA FP-30/40 bridge milling machine and one ZAYER KPCU 6000 AR DT bridge milling machine a second hand machine of which we will give you more details, after a brief explanation of what a bridge milling machine is and what it is for.

What is a bridge milling machine?

As many of you already know, a bridge milling machine is a machine-tool of chip removal which is used in the machining of big size pieces. The bridge milling machine has a work table located under the two columns of a bridge where the pieces move along. In that way, the tool can move either vertically or crosswise. There are two types of bridge milling machines: the ones which present a mobile bridge and the ones which have a fixed bridge. In the mobile bridge the table does not move, being the tool the one which makes the movement. However, in the milling machines of fixed bridge the movement is made by the table. In both cases we are talking of robust and versatile marchines.

NICOLAS CORREA FP-30/40 bridge milling machine

The NICOLAS CORREA bridge milling machine that we currently have on display at our showroom belongs to the FP series, undoubtedly one of the most demanded and successful models of the manufacturer of NICOLAS CORREA milling machines. This is the FP-30/40 model, which can work with two heads: the direct output head that reaches 6,000 rpm and a manual HURON 360º head of 3,000 revolutions.

Note that this machine has an extra measurement in the distance between columns, 2,000 mm, with the Y axis travel of 2,300 mm. Likewise, this used bridge milling machine is equipped with numerical control HEIDENHAIN 426.

The machine comes from a tool shop and is in exceptional condition, both mechanically and electronically speaking. It is an ideal milling machine for both the tooling sector and machining in general, for both heavy and large parts. It is a milling machine that perfectly combines robustness with dynamism. We invite you to come over to our facilities and see it under power and see for yourself all its benefits.

ZAYER KPCU 6000 AR DT bridge milling machine

This second-hand milling machine form the ZAYER brand presents high performance, that is why this machine contains in its name the letters "AR" which stand for "Alto Rendimiento" (the Spanish way to say "high performance). And what does it mean? That means it has more motor power, more engine torque and a bigger diameter of the vertical spindle.

But the wonders of this second hand milling machine are more. This ZAYER presents two remarkable aspects: first, it has a head of 0.001 accuracy which reaches 6,000 rpm, and allows to turn the two bodies simultaneously while the spindle is turning (3+2). The second thing to highlight is the fact that the machine is equipped with a double system table: it has two working areas of 3,000x2,000 mm that can work either indepently or combined, that is, a total working surface of 6,000x2,000 mm. This double table system, allows the user a great flexibility and a remarkably agility. Considering the two tables as two independent working areas, the operator can perform the machining on one piece and prepare another one for its finishing in another table. That means savings in time and, as a consequence, saving costs for the company. Just to put it in another words, this milling machine can perform the same tasks as a palletized machine.

In the list of extras of this ZAYER KPCU 6000 AR DT bridge milling machine, also mention that both the X and Y axes are rack and pinion, the machine has internal cooling, it has a 100-tool magazine, 2 chip extractors and it is equipped with a control HEIDENHAIN iTNC-530.

The distance between columns of this bridge milling machine is 2,800 mm, which makes it a very versatile machine for the heavy die sector, but it is also highly recommended for structures and machining in general.

More information

Both the NICOLAS CORREA FP-30/40 bridge milling machine and the ZAYER KPCU 6000 AR DT bridge milling machine are on display in our showroom based in the town of Parets del Vallès (Barcelona). If you want to see them, do not hesitate to contact us by phone at the number +34 935 730 225 or via email by writing to our email cecamasa@cecamasa.com to book an appointment. We will be delighted to show you these bridge milling machines, as well as our large stock of second-hand machinery that also includes bed type milling machines, traveling column milling machines, machining centers, CNC lathes, presses, shears, pressbrakes and a long etcetera of machines in the metallurgical sector. If you have a project and you need to invest in machinery, contact us and we will advise you in the best possible way. And if this pandemic has brought you an economic setback, don't worry, at CECAMASA we can put you in touch with financing experts who will study the feasibility of your project and will propose financial solutions tailored to your needs.

Measures taken by CECAMASA to face the COVID-19

Following the recommendations made by the Spanish government to address the pandemic caused by the COVID-19, the marketing department of CECAMASA has begun today to work remotely. It is an exercise in responsibility to our employees, customers and society in general. Despite the exceptional nature of these circumstances, we are working to ensure maximum normalcy in our services. We remain at your disposal to continue to provide you with information, resolving doubts and sending commercial offers of our machines via email: cecamasa@cecamasa.com / ventas@cecamasa.com or by phone +34 935 730 225.

Our technicians are carrying on working behind closed doors at our facilities and following a security protocol to ensure their welfare and prevent the spread of the virus. In this sense, external visits are not allowed. Once the situation goes back to normal, the visits will be re-scheduled.

We will keep you informed of any developments through social networks.

CECAMASA committed to GEMINIS lathes

In the wide stock of second-hand machinery of CECAMASA the lathes with numerical control are always present (cnc lathes). Along with the milling machines and the machining centers, the cnc lathes have a special place within our stock of used machinery. In the past we had in our portfolio production lathes of well-known makes such as CMZ, MAZAK, OKUMA, MORI SEIKI and many others. Nowadays, however, we have lathes of other great makes like DOOSAN or GEMINIS which are available for sale. Precisely, our post of March is focused on the above-mentioned make: GEMINIS.

CECAMASA SELLS A GEMINIS LATHE IN FRANCE

The company GEMINIS LATHES SA can be proud of its solid proven track record in the field of lathe production. Over 50 years in the market are enough proof of the quality of this company with international projection. Actually, its export figures are very impressive as they represent the 90% of its turnover. Those figures make this a leader company in the manufacturing of horizontal lathes of big dimensions and heavy machines. As we know about the greatness of GEMINIS, in CECAMASA we try our best to have cnc lathes of such excellent quality in our stock of second-hand machinery. In that sense, we are proud to inform you that this month we have sold to a French customer a GEMINIS GHT5 G2 lathe. It is a lathe equipped with a SIEMENS 810D control with a distance between centers of 4000 mm and a max swing over bed of 1000 mm. It is a machine of great performance and we are sure that it will be beyond the expectations of our French customer. A company located in the region of Rhône-Alpes with more than 15 years of experience in the machining of pieces which provides to customers from the energetic sector, aeronautics, railway and the automotive.

CECAMASA ACQUIRES A GEMINIS GHT5 G2 LATHE IN AN AUCTION

We have replaced that inventory issue with a new arrival equally attractive: a GEMINIS GHT5 G2 cnc lathe which presents the same distance between centers of 4000 mm and a max swing over bed of 1000 mm. However, in this case the machine has a FAGOR control. Moreover, it is equipped with a 4 independent jaw chuck of the make TdG with 900 mm diameter, a SAUTER automatic live tool turret with 290 mm diameter, automatic lubrication and chip conveyor. The lathe goes along with a boring support over carriage of 100 mm diameter, a steady rest of 430 mm diameter and several tools: 5 tool-holders, several points, sets of jaws, boring bars, etc. This lathe has been acquired from an auction, which also took place in France. This machine is located at our premises of the city of Parets del Vallès (Barcelona) and it is available for sale.

If you want more information on this second-hand GEMINIS GHT5 G2 cnc lathe, do not hesitate to contact us, you can write us an email to ventas@cecamasa.com or you can give us a call at +34 93 730 225. Our team of experts will be more than happy to answer all your questions and advise you in the best possible way. What are you waiting for?

CECAMASA sells a DAEWOO MYNX 540 machining center in Barcelona

During the last weeks, our team of technicians have been working thoroughly on the overhauling of a second-hand vertical machining center sold to a company based in Barcelona. It is a DAEWOO machining center model MYNX 540 equipped with FANUC control which increases the number of machines of our customer. An industrial supply company with over 80 years of experience in the market. The key of its success lies in combining technology and experience, as they have their own engineering department. We feel really honored that companies with such a proven track record in the market place their trust in us. But it comes as no surprise, as in CECAMASA we have a vast selection of second-hand machining centers in our warehouse placed in the city of Parets del Vallés (Barcelona). Within our selected range we have models of brands such as LAGUN, KONDIA, AWEA, DECKEL MAHO or DAEWOO. All of them brands of machining centers of great prestige, in the domestic market as well as in the international one.

TECHNICAL FEATURES OF THE DAEWOO MYNX 540 MACHINING CENTER

Daewoo is a Korean brand which is well-known in the segment of economical machinery of great performance. In the specific case of the DAEWOO MYNX 540 machining center we would like to highlight the fact that, although it presents a longitudinal traverse of 1,000 mm, the table area achieves 1,200 mm. Taking into account that plus the fact that the Z-axis travel is 625 mm, we are in front a machine that does not present the standard 500 mm in vertical. Its 8,000 rpm and its internal coolant supply, make this machine a very versatile and useful machine, especially for the mold and die sector of small size. Moreover, this second-hand machining center has a RANDOM tool changer of 24 units and it is equipped with a numerical control FANUC 21 iM digital.

OVERHAUL CARRIED OUT

Sticking to our usual plan of tasks, the DAEWOO MYNX 540 machining center has been previously checked thoroughly by our team of experts before proceeding with its sale. When in CECAMASA we buy a used machining center, our team of mechanics dismantles and checks it carefully in order to detect if a spare part needs to be repaired or replaced. Further to that diagnose, the needed actions are carried out and, of course, the geometry of the machine is tested to determine the degree of accuracy. All these steps are followed with the pursuit of ensuring that the second-hand machining center has the best possible quality, the closest to a new machining center. In this specific case, at mechanical level in this DAEWOO MYNX 540 machining center the bearings have been changed in all the axes,the spindles have been prestressed, the screw balls have been replaced and the turcite of the bed ways has been adjusted. All of it has been done in order to achieve correct accuracy degrees. Furthermore, the machine has been cleaned and painted and it looks as you can see in the below picture.

For further information about our range of second-hand machining centers, contact us. Write us an email to ventas@cecamasa.com or phone us at +34 935 730 225. We will be delighted to answer all your questions and we will advice you on the best possible way.

+ 34 935 730 225

+ 34 935 730 225