Liquidation of a boiler factory in the province of Barcelona (TRUPDEL)

In this post we want to inform you that CECAMASA has acquired a boiler shop located in the Barcelona area. It's about the company TRUPDEL, founded in 2011 and dedicated to meeting the needs of the industry by providing solutions in the metallurgical field to sectors as varied as food, pharmaceutical, plastic and wood processing, or machinery manufacturing, to name just a few.

The facilities of this boilermaker are located in the municipality of Mollet del Vallès, in the province of Barcelona. With more than 1,200 square meters dedicated to the manufacturing of its products, TRUPDEL has a significant park of machinery for the production of structures. In the sector of deformation of sheet metal We highlight the following press brakes, shears and bending machines currently available for sale through CECAMASA:

Hydraulic press brake 6×240Tn

It is a hydraulic press brake equipped with CYBELEC numerical control, model CYBTOUCH 8 with 2-axis control (X,Y). It has a presing force of 240 tons and a working length of 6050 mm. This used press brake is equipped with a manual compensation table, a pressure control from the CYBELEC control, 3 arms on the backgauge, as well as a 112x112 mm mouth die. Furthermore, the machine complies with CE regulations.

AJIAL 6x240Tn hydraulic press brake for sale

AJIAL 3x90Tn hydraulic press brake

We are talking about a second-hand hydraulic press brake with a pressing force of 90 tons and a working length of 3000 mm. It is equipped with a manual stop and a multi-mouth die with 9 mouths with a square diameter of 74 mm.

AJIAL 6x6mm hydraulic shear

This used hydraulic shear has a cutting length of 6100 mm, a thickness of 6 mm and a throat depth of 350 mm. The shear is equipped with a ball table, a set of blades, pneumatic blade adjustment, motorized stop measurement indicator panel, lighting of the cutting line, 1200 mm console, device for regulating the play between blades, device cutting length regulation, stroke count with zero setting and a set of wrenches and accessories for proper maintenance. Likewise, the machine complies with CE regulations.

AJIAL 6x6mm hydraulic shear for sale

AJIAL pendulum cutting 3x6mm shear

This second-hand shear features a cutting length of 3000 mm, a cutting thickness of 6 mm, a 310 mm throat depth and a 1000 mm motorized backgauge.

Pyramidal plate bending machine

It is a pyramidal bending machine with a maximum bending length of 2050 mm and a bending capacity of 6 mm. The diameter of the roller is 70 mm and the machine also has an extension of the shafts to install rollers.

A pyramidal plate bending machine is a machine tool used to bend metal sheets. It differs from a conventional plate bending machine in that the rollers of the machine are arranged in the shape of a pyramid. This design allows the machine to bend sheet metal with a smaller bend radius and a smoother finish.

Pyramidal plate bending machines are used in a variety of applications, including:

- Automotive Manufacturing: Used to bend sheet metal to form automotive parts, such as doors, roofs, and side panels.

- Appliance Manufacturing: Used to bend sheet metal to form appliance parts, such as ovens, refrigerators, and washing machines.

- Furniture Manufacturing: Used to bend sheet metal to form furniture pieces, such as chairs, tables, and sofas.

The benefits of pyramid plate bending machines include:

- Greater precision: Pyramid plate bending machines can bend sheet metal with a smaller bend radius, allowing for greater precision on curved parts.

- Higher Productivity: Pyramid plate benders can bend sheet metal faster than conventional plate benders.

- Greater Versatility: Pyramidal bending machines are a versatile tool that can be used to bend sheet metal for a variety of applications.

Asymmetrical plate bending machine

This used asymmetric plate bending machine has a maximum bending length of 1000 mm, a bending capacity of 3 mm and a roller diameter of 90 mm.

An asymmetrical plate bending machine is a machine tool used to bend sheet metal. It differs from a symmetrical plate bending machine in that the front and rear rollers have different lengths. This asymmetrical design allows the machine to bend metal sheets with a smaller bend radius.

In addition, the TRUPDEL boiler factory has other machines, vehicles and lifting elements of interest that we will detail below:

MG LEONARD 300 manual band saw

This is a second-hand band saw capable of cutting at 90º, 45º and 60º. The dimensions of the tape are 2750x27x0.9 mm and its cutting speed is 35-70 m/min. This MG LEONARD 300 saw is equipped with a roller track. The roller track of a saw is a system used to guide the workpiece across the saw blade. The rollers are designed to provide smooth, precise guidance, helping to ensure a straight, even cut.

The benefits of using a roller track on a saw include:

- Precision: Rollers provide smooth, precise guidance, helping to ensure a straight, even cut.

- Safety: Rollers can help reduce the risk of the workpiece spinning out of control during cutting.

- Ease of use: Rollers can make it easier and more comfortable to guide the workpiece through the saw blade.

MG LEONARD 300 band saw for sale

AUSIÓ double girder overhead crane

Likewise, the boilermaker has a double-girder overhead crane with a capacity of up to 12 tons and a span of 12 meters.

A double girder overhead crane is a type of overhead crane that has two rails on which the load-carrying car slides. This type of crane is more versatile than monorail bridge cranes, as it can lift loads from any point in the space under the bridge.

Double girder overhead cranes are used in a variety of applications, including:

- Manufacturing industry: to move heavy and bulky materials in factories.

- Warehousing: to lift and move pallets of goods in warehouses.

- Construction: to lift and move construction materials on construction sites.

Double girder overhead cranes have a number of advantages over single girder overhead cranes, including:

- Greater versatility: Double girder overhead cranes can lift loads from any point in the space beneath the bridge.

- Higher load capacity: Double girder overhead cranes can support heavier loads than single girder overhead cranes.

- Greater safety: Double girder overhead cranes have a safer design than single girder overhead cranes.

NISSAN CABSTAR E truck

In the list of assets we could not fail to mention a NISSAN truck model CABSTAR E, diesel registered on November 6, 2002 and with 355,231 kilometers traveled.

The Nissan Cabstar E is a light truck that offers a combination of performance, efficiency and capability. It is a good choice for a variety of commercial applications, such as freight transportation, construction and cleaning.

To the detailed list, we must add that the boiler shop is equipped with different models of welding, pallet jacks, a FORMIS belt polishing machine, etc.

If after reading this post you are left wanting to know more, do not hesitate to contact us and we will give you more details about our latest acquisition. You can call us at the company phone number +34 935 730 225 or send us an email to ventas@cecamasa.com.

AJIAL 630 shearing machine

Characteristics of the second-hand AJIAL 630 pendulum cutting shearing machine

| Reference: | 031/B039 | |

| Cutting length: | 3000 mm | |

| Cutting thickness: | 6 mm | |

| Throat depth: | 310 mm | |

| Motorized backgauge: | 1000 mm | |

| Engine power: | 15 cv |

Do you need more information about this second-hand AJIAL 630 shearing machine?

Contact us and we will inform you without any commitment on this AJIAL shear. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

AJIAL CS-650 shearing machine

Features of the second-hand AJIAL CS-650 hydraulic shearing machine

| Reference: | 031/B034 | |

| Cutting length: | 6100 mm | |

| Cutting thickness: | 6 mm | |

| Throat depth: | 350 mm | |

| Distance between frames: | 6250 mm | |

| Gauge length: | 1000 mm | |

| Cutting angle: | 1st 24' fixed | |

| Cuts per minute: | 12 | |

| Hydraulic pump flow: | 68 l/mm | |

| Pump motor pressure: | 120 bar | |

| Engine power: | 20 cv | |

| Number of blades: | 8 | |

| Blade section: | 57x20 mm | |

| Number of rammers: | 25 | |

| Ø rammers: | 70 mm | |

| Total rammers force: | 40 Tn | |

| Oil tank capacity: | 250 l | |

| Approx machine weight: | 15.000 Kgs | |

| Machine site: | 6680x2500x2030 mm | |

| Equipped with: | ||

| Ball table: | Yes | |

| Blade set: | lower and upper | |

| Blade adjustment: | pneumatic | |

| Measurement indicator panel: | of the motorized backgauge | |

| Cutting line lighting | ||

| Console: | 1200 mm | |

| Blade gap adjustment device: | Yes | |

| Cutting length regulation device: | Yes | |

| Stroke counter with resetting to 0: | ||

| 1 set of wrenches and accessories for maintenance | ||

| CE standards: | yes |

Do you need more information about this second-hand AJIAL CS-650 hydraulic shearing machine?

Contact us and we will inform you without any commitment on this AJIAL hydraulic shear. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

GEKA shear punching machine

Characteristics of the second hand GEKA HYDRACROP 100 SD shear-punching machine

| Reference: | 031 / Z016 | |

| Shear for rims | ||

| Slightly deformed rim: | 600x15 mm - 400x20 mm | |

| Blades' length: | 605 mm | |

| L at 45º: | 100x100x13 mm | |

| Working height: | 960 mm | |

| Shear for profiles | ||

| L at 90º: | 150x150x13 mm | |

| L at 45º: | 70x70x7 mm | |

| Shear for bars | ||

| Round bar: | 50 mm | |

| Square bar: | 50 mm | |

| Notching | ||

| Metal sheet: | 13 mm | |

| L: | 100 mm | |

| Depth: | 90 mm | |

| Width: | 52 mm | |

| Punching | ||

| Punching power: | 100 Tn | |

| Maximum capacity: | Ø31x26 mm | |

| Gap: | 610 mm | |

| Stroke: | 80 mm | |

| Working height: | 1165 mm | |

| Approximate machine weight: | 3100 kgs | |

| Machine dimensions: | 2550x1200x2270 mm | |

| Equipped with: | ||

| More than 250 punches and dies |

Do you need more information about this second hand GEKA HYDRACROP 100SD shear-punching machine?

Contact us and we will inform you without any commitment on this hydraulic punching machine . Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

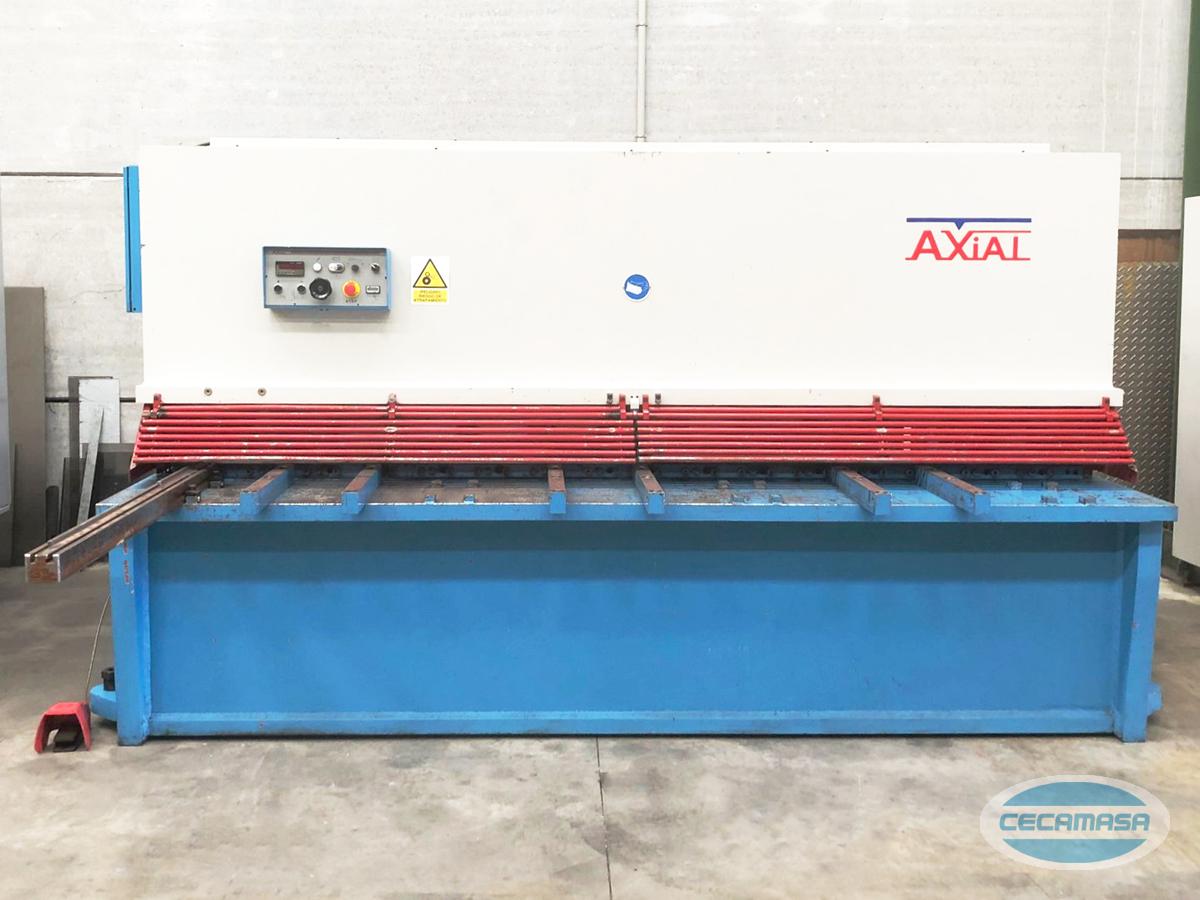

AXIAL CP 1630 shear

Technical features of the used AXIAL CP 1630 hydraulic shear

| Reference: | 031/Z015 | |

| Cutting length: | 3100 mm | |

| Cutting thickness: | 16 mm | |

| Throat depth: | 350 mm | |

| Distance between frames: | 3290 mm | |

| Cutting angle: | 2º | |

| Cuts per minute: | 8-12 | |

| Pump motor power: | 50 CV | |

| Blade section: | 100x40 mm | |

| Number of rammers: | 25 | |

| Approx machine weight: | 16.000 Kgs | |

| Machine dimensions: | 3800x2500x2050 mm | |

| Equipped with: | ||

| Hengstler digital backgauge: | 1175 mm of length | |

| Ball table: | Yes | |

| Manual wheel: | for accurate approach of the gauge | |

| Digital counter for number of cuts: | Yes | |

| Adjustment of the cutting length: | Yes | |

| Lighting and projection of the cutting line: | Yes | |

| Front protection grille: | folding | |

| Hold down force with independent regulation: | Yes | |

| Safety photocells: | at the rear of the machine |

Do you need more information about this second hand AXIAL CP 1630 hydraulic shear?

Contact us and we will inform you without any commitment on this hydraulic shear AXIAL. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

Shears

The KLISMAN shear is a machine made of welded steel with excellent rigidity and stability. The main parts consist of left and right pillars, clamping board, a working talbe and oil tank.

Upper knife beam: a triangle steel-sheet welded structure with guiding rail plate, blade and back-gauge device.

The blade adjustment is very easy to use, it is carried out through a front wheel indicating the thickness of the sheet to be cut.

The table is equipped with balls to facilate the handling of the sheet.

The machine is fitted with a nitrogen accumulator, which it uses for the return of the blade and damping in the cut.

Machine description

- Vertical cutting and variable angle shear

- 4 side blades (up and down)

- ES21 numerical control - 2 axes (motorised back-gauge and blade tilt)

- Front wheel for blade clearance

- Front folding grid

- 3 front arms

- Steel ball table

- Pedal

- TELEMECANIQUE electrical components

- Rear safety lights (CE regulation)

- Cut off light

- Stroke counter

Klinsman

Klinsman is one of the largest manufacturers worldwide of shears and hydraulic brakes.

Their machines are characterized by their high rigidity and reliability at work. From conventional machines to CNC machines.

CECAMASA leads since 2000 with distribution in Spain, Portugal and part of South America with the guarantee of the sale of a product of great features and performance guarantee.

The machining of the machines is carried out on the structure of the machine already welded in order to avoid deformations. Top-quality brands such as Telemecanique or Schmersal are integrated into the electrical part and both assembly and painting follow an order and care established for its proper functioning during the useful life of the machine.

+ 34 935 730 225

+ 34 935 730 225