CECAMASA expands its stock of second-hand traveling column milling machines

Currently in CECAMASA we have a total of 4 second-hand traveling column milling machines available for sale. Three of these traveling column milling machines have been recently acquired and all of them are from the prestigious SORALUCE brand.

Soraluce is a Spanish company founded in 1965 that is dedicated to the design, manufacture and sale of CNC machine tools. The company is a world leader in the milling machine sector, and its machines are used in a wide range of industrial applications, including the manufacture of metal parts, molds and dies, tools and fixtures, as well as industrial maintenance.

The Soraluce range of milling machines includes benchtop machines, bed type machines, traveling column machines and gantry machines. Always committed to technological innovation, Soraluce brand machines are equipped with the latest technologies. It is an ideal option for companies looking for a CNC milling machine that provides optimal performance and long life.

Now that we have told you about the reputation that precedes SORALUCE, we are going to do a little pedagogy and explain what a mobile column milling machine is and what it is for. And then we will list the capacities of the 3 second-hand traveling column milling machines newly added to our inventory.

What is a traveling column milling machine?

A traveling column milling machine is a machine tool that uses a milling cutter to machine metal parts. The milling cutter is a rotating tool with several teeth that are used to cut, carve or roughen the part. The moving column milling machine has a vertical column that supports the milling head, which can move in three directions: horizontal, vertical and axial.

Parts of a traveling column milling machine

The main parts of a traveling column milling machine are:

- Column: Supports the milling head.

- Milling head: Contains the main spindle, which rotates the milling cutter.

- Work table: Supports the part to be machined.

- Guides: Allow movement of the column and milling head

- Control: Allows programming of machining operations.

Applications of traveling column milling machines

Traveling column milling machines are used in a wide range of industrial applications, including:

- Manufacturing of metal parts: Traveling column milling machines are used to machine metal parts of any shape and size. Some of the machining operations that can be performed with a moving column milling machine are: drilling, tapping, profiling, grooving, roughing and finishing.

- Mold and die manufacturing: Traveling column milling machines are used to machine molds and dies, which are used to manufacture parts from plastics and other materials.

- Manufacturing of tools and fixtures: Traveling column milling machines are used to machine tools and fixtures, which are used to manufacture other parts.

- Industrial maintenance: Traveling column milling machines are used to repair and maintain metal parts.

Traveling column milling machines offer a number of advantages, including:

- Versatility: Traveling column milling machines can perform a wide range of machining operations.

- Precision: Traveling column milling machines can provide high machining precision.

- Productivity: Traveling column milling machines can increase machining productivity.

Disadvantages of traveling column milling machines

Traveling column milling machines also have some disadvantages, including:

- Cost: Traveling column milling machines are large, high-capacity machine tools, so their cost is high.

- Space requirement: Traveling column milling machines require a large amount of space for installation.

Now that we have seen what a traveling column milling machine is and what it is for, we will explain in detail the 4 machines that make up our stock in this category:

SORALUCE SL 8000 traveling column milling machine

The traveling column milling machine SORALUCE SL 8000 is a large, high-capacity CNC machine tool used in a wide variety of industrial applications. It is a robust and reliable machine, offering excellent performance and productivity.

Advantages

- Large size and capacity: The SL 8000 has a 8000 x 800 mm work table, which allows working with large pieces. In addition, it has a longitudinal travel (X) of 6500 mm, a transverse travel (Y) of 1000 mm and a vertical travel (Z) of 1600 mm.

- Excellent performance and productivity: the machine has a Heidenhain iTNC 530 CNC control, which allows complex machining operations to be programmed and executed simply and efficiently.

- Robustness and reliability: The SL 8000 is manufactured with high quality materials and is designed to offer great resistance and durability.

Conclusion

The SORALUCE SL 8000 traveling column milling machine is a large, high-capacity CNC machine tool that offers a wide range of advantages: robustness and reliability, as well as high productivity. However, its need for space can be a drawback for some companies.

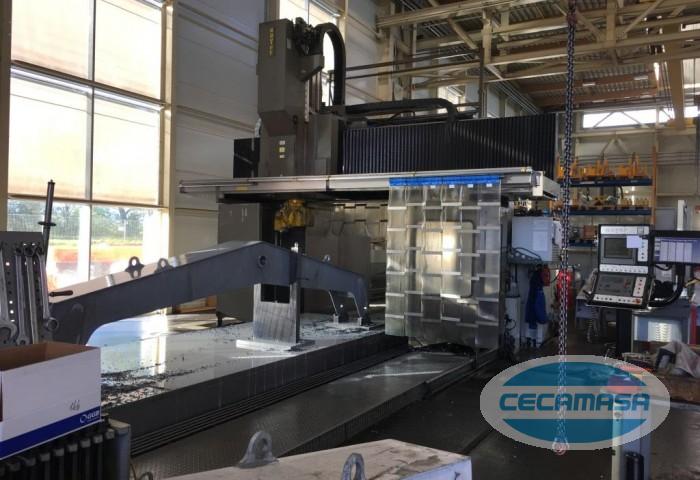

SORALUCE SL 8000 traveling column milling machine

SORALUCE SP 6000 traveling column milling machine

The traveling column milling machine SORALUCE SP 6000 It is also a large and capable CNC machine tool that offers multiple advantages. Below we are going to cite some of them:

Advantages

- Large size and capacity: The SP 6000 has a 6000 x 1100 mm work table, which allows working with large pieces. In addition, it has a rack-and-pinion longitudinal travel (X) of 4500 mm, a transverse travel (Y) of 1200 mm and a vertical travel (Z) of 2000 mm, which offers great versatility in machining parts of any shape. and size.

- Excellent performance and productivity: The SP 6000 is equipped with a main spindle that reaches 5000 rpm, which results in high cutting speeds and feeds, and therefore increased productivity. It is also equipped with a HEIDENHAIN iTNC 530 control.

- Equipment: This second-hand traveling column milling machine is very well equipped. It has an elongated 90º milling head (500 mm), two front supplementary tables of 1500x1200x1000mm and 2 squares of 2250x800x1200mm.

Conclusion

Simply put, the SORALUCE SP 6000 traveling column milling machine is a versatile and reliable CNC machine tool, which is suitable for a wide range of industrial applications. It is an ideal machine for companies that need to machine large parts with precision and efficiency.

SORALUCE SP 6000 milling machine

SORALUCE SV-HSC 8000 traveling column milling machine

Once again we are talking about a milling machine from the prestigious SORALUCE brand in its traveling column mode. SORALUCE SV-HSC 8000 with a long list of advantages that we are now going to explore.

Advantages

- Large size and capacity: The SV-HSC 8000 has a work table of 8000 x 1100 mm, which allows working with large pieces. In addition, it has a rack and pinion longitudinal travel (X) of 7000 mm, a transverse travel (Y) of 2000 mm and a vertical travel (Z) of 1200 mm.

- Excellent performance and productivity: The SV-HSC 8000 is equipped with a 1º-1º automatic octagonal head.

- HSC technology: The SV-HSC 8000 is equipped with HSC technology, which allows extremely high cutting speeds and feeds to be achieved. This makes it an ideal machine for machining large parts with precision and efficiency.

- Equipment: This second-hand traveling column milling machine is very well equipped. It has two front supplementary tables of 1000x1200x1000mm, 2 squares of 1000x1200x3500mm and a thermal compensation probe.

Conclusion

The SORALUCE SV-HSC 8000 traveling column milling machine is a large, high-capacity CNC machine tool with high speeds and cutting capabilities and a very robust head and structure. In addition, it is equipped with HSC technology, which makes it an ideal machine for machining large parts with precision and efficiency. However, their need for space can be a disadvantage for some companies with limited space.

SORALUCE SV-HSC 8000 milling machine

ZAYER 30 KCU 16000 AR traveling column milling machine

To the previous traveling column milling machines from the SORALUCE brand, we have to add that in our stock we have a milling machine from this category from the ZAYER brand. A “Made in Spain” brand that also enjoys a great reputation. If you want to know more about this machine, I invite you to visit our post “CECAMASA completes the retrofitting of the star machine in its inventory: the ZAYER 30 KCU 16000 AR traveling column milling machine”.

More information

If you want to know more about our traveling column milling machines or any other machine in our extensive inventory, do not hesitate to contact us through Whatsapp in the number +34 678 66 3584 or write us a message to the email address ventas@cecamasa.com.

CECAMASA COMPLETES THE RETROFITTING OF THE STAR MACHINE OF ITS INVENTORY: THE ZAYER 30 KCU 16000 AR TRAVELING COLUMN MILLING MACHINE

What is the retrofit or retrofitting of machinery?

The English term "retrofit” could be translated as “reconditioning”. In fact, this term applied to the field of machinery refers to the updating or reconstruction of industrial machines to make them competitive again. These actions can be carried out on mechanical, hydraulic, electronic components, etc. The point is that these interventions lead to improvements in their productivity and accuracy. No doubt the retrofit it is an excellent alternative to buying new equipment goods. In CECAMASA we are aware that the majority of the Spanish industrial fabric is made up of SMEs with modest budgets that need to replace their machinery at reasonable costs. For this reason, our team of highly qualified technicians strives every day to recondition our fleet of second-hand machinery to leave each machine as if it were new.

In this post we are going to talk about our latest work: the retrofit of a traveling column milling machine of the prestigious ZAYER brand, model 30 KCU 16000 AR with a longitudinal travel of 16 meters. Currently, the largest machine in our inventory and therefore our crown jewel.

Works carried out on the retrofitting of the ZAYER 30 KCU 16000 AR milling machine

Our team of technicians has required two months of hard work to get this impressive ZAYER traveling column milling machine ready. A second-hand milling machine that comes from a Central European company dedicated to the construction of mega metal structures. Broadly speaking, the works that have been carried out have been the following:

– Assembly of the guides, always looking for their parallelism

– The column assembly

– The installation of the pick-up of heads

– The replacement of the guide shoes

– Verification of the geometry of the machine.

The assembly of the machine has been possible thanks to the means we have. In this sense, we refer both to the professionalism of our technicians and to the tools they have used to carry out their mission. Among these tools, a Renishaw interferometer laser stands out, which allows the verification of machine geometries with dimensions of up to 20 meters. The laser interferometer is emerging as the most advanced technology to date for obtaining highly accurate information. In addition, as it is a non-contact measurement method, mechanical deterioration of the system is avoided.

Renishaw laser interferometer

Likewise, the ballbar has also been used to check the geometry of the interpolation of the 3 axes. With the ballbar a quick verification of the positioning performance of the machine is obtained. In this way, the technician can analyze the condition of the machine and detect the problems that require maintenance and determine their causes.

With the use of this cutting-edge technology, it has been possible to recondition this large-sized ZAYER mobile column milling machine to achieve a good geometry of the machine without it having the necessary foundation for its optimal operation. An achievement that we are proud of.

Highlights of the ZAYER 30 KCU 16000 AR milling machine

This second-hand ZAYER milling machine has great attractions: from a engine torque higher than normal, passing through shafts equipped with rack and pinion to the pick-up of heads that the machine has installed. This pick-up has two heads: the famous ZAYER head with 0.001 precision in the body A and B in 360,000 positions and a head of the brand d’ANDREA UT 5/500 S model that allows boring with a diameter of up to 800 mm. This duality of heads gives this machine great versatility since it allows both machining to be carried out on any type of part (metal structure, moulds, dies, etc.), as well as very deep boring, such as making large holes in hydraulic blocks.

In addition, this second-hand milling machine has fixed tables of the brand Rübenach, a rotary table of the brand PEISELER 2500×2500 mm with a capacity of up to 20 tons, a 100-tool magazine, chip conveyor, internal coolant, an operator's cabin with elevation and numerical control HEIDENHAIN iTNC 530.

MORE INFORMATION

If you want to know more about this ZAYER 30 KCU 16000 AR traveling column machine or any other machine from our extensive inventory, do not hesitate to contact us through Whatsapp at the number +34 678 66 3584 or write us a message to the email address ventas@cecamasa.com.

CECAMASA EXPANDS ITS STOCK WITH A SECOND-HAND ZAYER XIOS 4000 BED TYPE MILLING MACHINE

At CECAMASA we start this 2022 with the acquisition of a ZAYER XIOS 4000 bed type milling machine. This excellent second-hand machine joins our extensive catalog of second-hand milling machines available for sale. Those of you who already know us already know that at CECAMASA we always like to have ZAYER, SORALUCE or CORREA milling machines in stock. Brands produced domestically that with their know-how have crossed borders and offer great results. This used ZAYER milling machine in particular comes from a company based in Basauri (Basque Country) dedicated to precision machining with applications in the wind and aeronautical sectors. It is a bed type milling machine from the prestigious ZAYER brand, manufactured in 2014 and installed in the house of its previous owner in mid-2015.

MOST RELEVANT FEATURES OF THIS ZAYER MILLING MACHINE

As main technical characteristics we would like to mention its 1500 mm traverse (Y axis) and 1600 mm vertical (Z axis) travese. Likewise, it presents an automatic head with 360,000 positions in both bodies. A milling machine that is also very well equipped with a long list of extras, such as: internal cooling, chip conveyor or paper filter tank. Without forgetting that the machine is sold together with 3 squares, 2 prisms for supporting and machining rollers, 2 ARNOLD hydraulic vices with 200 mm jaws and a set of tools.

Another factor to mention is that the spindle of this milling machine has only approximately 1,700 hours of work. This responds to the fact that its previous owner has decided to retire and the business has ceased its activity after his retirement. So we are talking about a second-hand milling machine that could well be described as "half-new" given the excellent conditions it is in and the little wear it has suffered. On our website you can find the technical data sheet corresponding to this Zayer millling machine in our option of the menu Used machinery - Bed type milling machines.

POSSIBILITY OF SEEING THE MILLING MACHINE UNDER POWER

This milling machine can be seen under power by appointment at the facilities of its previous owner, that is, in Basauri. However, to whet your appetite, we leave you with a video of it so that you can see for yourselves that we are far from exaggerating when we say that it is a great machine with excellent features:

MORE INFORMATION

If this post has aroused your curiosity and you want to know more about this ZAYER XIOS 4000 bed type milling machine or any other machine in our inventory, do not hesitate to contact us. You can call us at +34 935 730 225, contact us through Whatsapp at the number +34 678 66 3584 or write us an email at ventas@cecamasa.com. At CECAMASA we will be happy to assist you and put at your disposal our almost 40 years of experience in the sector.

CECAMASA committed to milling machines "made in Spain"

As many of you may already know, milling machines feature prominently in our wide selection of used machinery. Currently all of our second-hand milling machines available for sale are taken over by Spanish brands. In CECAMASA are committed to manufacturers of milling machines "made in Spain” as exponents of high quality machinery, great performance and high precision. Next, we are going to talk about these manufacturers who, with their good work, have crossed borders and have made a name for themselves internationally.

ZAYER milling machines

Zayer, based in Vitoria-Gasteiz (Basque Country), it defines itself as a machine tool company with an “entrepreneurial spirit and innovative capacity”. Not surprisingly, Zayer has more than 60 years of experience designing and manufacturing milling machines (bed type milling machines, bridge milling machines, gantry milling machines, moving column milling machines) and machining centers. In addition to having a long history in the market, ZAYER has a wide commercial network that includes its own offices in countries such as Italy, Brazil and China. They can also boast a highly qualified technical assistance service that operates in more than 40 countries.

At CECAMASA we are proud to have a ZAYER bed type milling machine, a ZAYER mobile column milling machine and a bridge milling machine from the same brand. In our post “Wide selection of bed type milling machines in CECAMASA" you will find detailed information about our ZAYER 30KF-5000 bed type milling machine.

On the other hand, we have a ZAYER 30 KCU 16000 AR a mobile column milling machine, a top model from this manufacturer. That machine is in excellent mechanical condition. Its generous 16,000 mm longitudinal, 1,500 mm transverse and 3,500 mm vertical travels, make this milling machine an ideal machine for machining heavy and large parts. Therefore, we speak of a robust, reliable and precise machine. Also, we would like to highlight of this the mobile column milling machine, the chip conveyor, the internal cooling, the operator's cabin with elevation and the numerical control HEIDENHAIN iTNC 530.

If you want to know more about this machine, we encourage you to consult its technical data sheet where you will find detailed all its specifications. Finally, we have a ZAYER KCPU 6000 AR DT bridge type with double table system. It is a very versatile milling machine and highly recommended for the heavy tooling sector and for structures. We also encourage you to consult its technical data sheet so that you can get an idea of all the benefits it can offer.

SORALUCE milling machines

Soraluce is another of the great Spanish machine tool manufacturers. Based in Bergara (Basque Country), Soraluce is part of the DANOBATGROUP business group, one of the most important in all of Europe. With an experience of more than 50 years in the market, its success, according to its website, is based on "excellent quality, star service and cutting-edge technology." SORALUCE reveals itself as a leading company in milling, boring and turning technology with an international projection. Its business strategy is based on 4 pillars: development of leading technology, commitment to the digitization of the company, highly qualified service and the aspiration to manufacture less polluting machines.

Nowadays, in CECAMASA we have three bed type milling machines of the brand SORALUCE: Soraluce TA-35, Soraluce TA A-20 and SORALUCE TA-20. In our post “Wide selection of bed type milling machines in CECAMASA" you will find detailed information about our Soraluce TA-35 bed type milling machine. Regarding the SORALUCE TA-20 milling machine, although among the three SORALUCE series, the TA series is the lightest, this does not mean that it is the worst machine. In fact, this bed type milling machine provides a high speed of axis translation with linear guide and is in a geometry of 0.02. It also has a full enclosure, has a chip conveyor and it is equipped with HEIDENHAIN control. Finally, our SORALUCE TA A-20 milling machine apart from having a full enclosure, chip conveyor, HEIDENHIAN control, it is as well equipped with a tool changer of 20 units.

NICOLAS CORREA milling machines

The company NICOLAS CORREA SA, based in Burgos, it was founded in 1947 and is dedicated to the design and manufacture of medium and large size milling machines. On their website they highlight that both the design and manufacture of their machines are carried out entirely in Europe. They have a commercial network, as well as a technical service, at an international level. Aware of the growing concern for environmental issues, NICOLAS CORREA has the ISO 14001 Certificate for Environmental Management. This certification accredits quality standards and respect for the environment.

Today at the premises of CECAMASA we have a Nicolas Correa bed type milling machine: the Nicolas Correa A30/40 milling machine, which has an automatic head and a central support in the table with T-slots. That support allows to fix pieces at the table side.

Moreover, we have a NICOLAS CORREA FP-30/40 bridge milling machine. The FP series is one of the best-sellers of this manufacturer. This bridge milling machine can work with two heads: the direct output head (6,000 rpm) and a 360º manual HURON head (3,000 rpm). It is equipped with a HEIDENHAIN 426 numerical control.

LAGUN milling machines

LAGUN MACHINE TOOLS, S.L. is another manufacturer of bed type milling machines and mobile column milling machines based in the Basque Country, specifically in Azkoitia. This Basque company has been manufacturing milling machines for more than 60 years. As stated on their website, their business strategy is based on focusing on "the design and manufacture of medium-sized milling machines, at a competitive price and proven reliability." One fact to highlight is that they allocate more than 10% of their staff to the R + D + I department. Their main market is Europe, with Germany topping the list, although they also export to markets such as India, Turkey, the US and Canada. With a broad export vocation, LAGUN has a qualified technical service to respond to its international customers.

Currently, at CECAMASA we have two LAGUN bed type milling machines, both belong to the GBR3 model, the only difference between them is their year of manufacture, one dates from 2011 and the other from 2013. Both LAGUN GBR3 milling machines they are equipped with HEIDENHAIN iTNC-530 control, have through-shaft cooling and a chip conveyor. Likewise, it should be noted that they are equipped with an automatic 2.5º-2.5º head that reaches 3,000 rpm.

More information

We hope this post has aroused your interest and you want to know more about our milling machines "made in Spain". If so, do not hesitate to contact us through our email address cecamasa@cecamasa.com or by calling us at +34 935 730 225. Our team of sales representatives and technicians will answer all your questions.

+ 34 935 730 225

+ 34 935 730 225