FAVRETTO tangential

Technical characteristics of the second-hand FAVRETTO RTB 2000 tangential grinder

| Reference: | 163-N312 | |

| Table dimensions: | 2000x400 mm | |

| Max width to grind with a wheel: | 430 mm | |

| Max longitudinal traverse: | 2150 mm | |

| Max height to grind: | 508 mm | |

| Spindle speed: | 1400 rpm | |

| Main motor power: | 12 CV | |

| Grinding wheel dimensions: | Ø 400x50x127 mm | |

| Magnetic chuck dimensions: | 1510x405 mm | |

| Approx machine weight: | 6700 kgs | |

| Machine dimensions: | 5530x1830x2600 mm |

Do you need more information about this second-hand FAVRETTO RTB 2000 tangential grinding machine?

Contact us and we will inform you without any commitment on this tangential grinding machine. In addition, if you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

CHEVALIER tangential

Technical characteristics of the second-hand CHEVALIER FSG-1228AD tangential grinding machine

| Reference: | 163-TM43 | |

| Table dimensions: | 700x300 mm | |

| Grinding length: | 710 mm | |

| Grinding width: | 305 mm | |

| Max distance from the table to the spindle centerline: | 500 mm | |

| Approx machine weight: | 2300 Kgs | |

| Floor ocupation: | 3000x1490x1930 mm | |

| Equipped with: | ||

| Control: | Chevalier | |

| Electromagnet: | 500x260 mm | |

| New replacement spindle |

Do you need more information about this second-hand CHEVALIER FSG-1228AD tangential grinding machine?

Contact us and we will inform you without any commitment on this tangential grinding machine. In addition, if you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

DANOBAT HG 91-3000-B8 cylindrical int+ext cnc

Technical characteristics of the second-hand DANOBAT HG 91-3000-B8 cnc cylindrical grinding machine

| Reference: | 161-C001 | |

| Max grinding length: | 3000 mm | |

| Centers' height: | 525 mm | |

| Max grinding diameter: | 850 mm | |

| Max allowed weight: | 5000 kgs | |

| X-axis | ||

| Stroke: | 650 mm | |

| Max speed: | 6000 mm/min | |

| Min speed: | 0,01 mm/min | |

| Torque: | 22.4 N.m | |

| Z-axis | ||

| Max speed: | 6000 mm/min | |

| Torque: | 42 N.m | |

| B8 axis (head) | ||

| Rotation angle: | -30 / +180 | |

| Head dimensions: | Ø760x100xØ304.8 | |

| Power: | 22 kW | |

| Working head | ||

| Head speed: | 10+120 min-1 | |

| Torque: | 42 N.m. | |

| Max accuracy cone: | ±0,20 mm | |

| Weight and measurements | ||

| Weight: | 29.000 kgs | |

| Equipped with: | ||

| Various sets of grinding wheels | ||

| Various sets of backplates for grinding wheels | ||

| Steady rests | ||

| MARPOSS workpiece measuring probe "gantry type" | (at full working capacity - 3 meters) | |

| Grinding wheel wear measuring probe | ||

| Internal cooling with paper filter |

Do you need more information about this second-hand DANOBAT HG 91-3000-B8 cnc cylindrical grinding machine?

Contact us and we will inform you without any commitment on this DANOBAT cylindrical grinding machine. In addition, if you wish, you can also visit our facilities located in Parets del Vallés (Barcelona). We have all kinds of new and used industrial machinery: conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, machining centers, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

Tangential DANOBAT RT-800

Technical characteristics of the second-hand DANOBAT RT-800 tangential grinding machine

| Reference: | 163-Z031 | |

| Table dimensions: | 1000x450 mm | |

| Longitudinal traverse (X-axis): | 800 mm | |

| Cross traverse (Y-axis): | 500 mm | |

| Vertical traverse (Z-axis): | 450 mm | |

| Automatic lowering: | Yes | |

| Grinding wheel dimensions: | 350x100 mm | |

| Approximate weight: | 5000 Kgs | |

| Equipped with: | ||

| Magnetic chuck: | 800x350 mm | |

| Magnetic chuck: | 500x200 mm | |

| Diamond grinder wheel: | Yes |

Do you need more information about this second-hand DANOBAT RT-800 tangential grinding machine?

Contact us and we will inform you without any commitment on this DANOBAT tangential grinding machine. In addition, if you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

ESTARTA301 MV centerless

Information of the used ESTARTA 301 MV centerless grinding machine

ESTARTA, as SORALUCE, belongs to DANOBATGROUP. DANOBATGROUP is the most important business group of machine tool manufacturing nationwide.

ESTARTA is characterized by being one of the most accurate machines in the grinding field. This second hand ESTARTA 301 MV centerless grinding machine is equipped with a control FANUC. This machine has been overhauled by our technical team and can do lots of works. It can work both in in-feed as in through-feed.

This second-hand centerless grinding machine is very well equipped and it can be seen on our premises.

Technical features of the second hand ESTARTA 301 MV grinding machine

| Reference: | 165-B017 | |

| Min-max grinding diameter: | 1,5-50 mm | |

| In-feed grinding length (max): | 125 mm | |

| Grinding wheel dimensions (ODxWidthxID): | 300x125x175 mm | |

| Regulating wheel dimensions (ODxWidthxID): | 220x125x125 mm | |

| OD (min) grinding wheel: | 220 mm | |

| OD (min) regulating wheel: | 165 mm | |

| Grinding wheel peripheral speed: | 35 m/s | |

| Regulating wheel speeds: | De 10 and 250 min -1 | |

| Height dresser regulator regulating wheel: | +15 / -10 mm | |

| Max grinding and regulating wheel's profile depth: | 8 mm | |

| Max working wheel orientation: | 30º | |

| Diamond wheel feed rate: | 100-150 mm/min | |

| Grinding wheel power: | 7,5 kW | |

| Regulating wheel power: | 0,75 kW | |

| Approximate machine weight: | 1.800 kgs | |

| Machine dimensions: | 2525x1942x1450 mm | |

| Year: | 2008 | |

| Equipped with: | ||

| Numerical Control: | FANUC | |

| In through and in-feed grinding | ||

| Vibrator feeder with automatic loading and unloading manipulator | ||

| Grinding wheel balancing bars |

Do you need more information about this second hand ESTARTA 301 MV grinding machine?

Contact us and we will inform you without any commitment on this ESTARTA 301 MV grinding machine. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

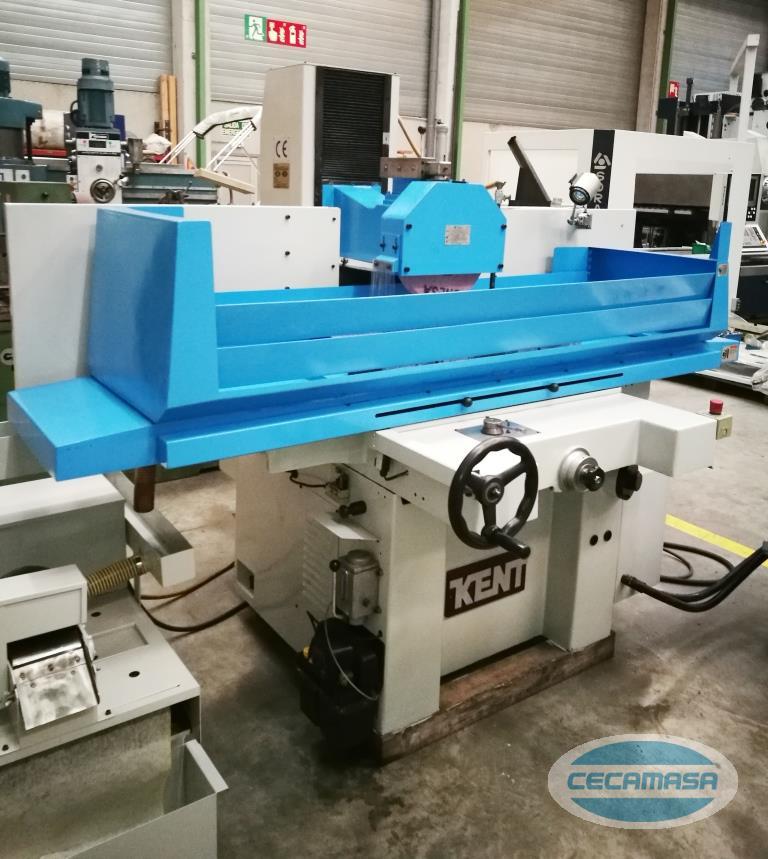

KENT KGS-84 tangential grinder

Technical features of the second-hand KENT KGS-84 SD1 tangential grinder

| Reference: | 163-Z029 | |

| Table travel: | 930 mm | |

| Longitudinal traverse (X-axis): | 880 mm | |

| Cross traverse (Y-axis): | 450 mm | |

| Height from table to center of the axis: | 590 mm | |

| Grinding wheel dimensions: | Ø 350x50 mm | |

| Grinding wheel speed: | 1730-60 Hz / 1440-50 Hz | |

| Grinding wheel power: | 3.7 kw | |

| Approximate weight: | 2800 Kgs | |

| Machine dimensions: | 2500x1800x2000 mm | |

| Equipped with: | ||

| Kent electromagnetic chuck: | 800x400 mm | |

| Paper filter diposit: | Yes |

Do you need more information on this second-hand KENT KGS-84 SD1 tangential grinding machine?

Contact us and we will inform you without any commitment on this KENT tangential grinder. In addition, if you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

GER RS-10/50 tangential

Technical characteristics of the used GER RS-10/50 tangential grinder

| Reference: | 163-ME14 | |

| Table dimensions: | 1000x550 mm | |

| Distance from table to center of grinding wheel: | 625 mm | |

| Table speed: | 2 to 25 | |

| Max grinding weight: | 1000 kgs | |

| Longitudinal traverse (X-axis): | 1050 mm | |

| Cross traverse (Y-axis): | 500 mm | |

| Automatic penetration: | Yes | |

| Grinding wheel dimensions: | Ø 400x80x127 mm | |

| Grinding wheel head: | 12.5 CV | |

| Hydraulic pump power: | 5.5 CV | |

| Equipped with: | ||

| Electromagnet: | 760x500 mm |

Do you need more information about this second hand GER RS-10/50 tangential grinding machine?

Contact us and we will inform you without any commitment on this GER grinder. In addition, if you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

CHEVALIER FSG-1632AD tangential

Technical characteristics of the used CHEVALIER FSG-1632AD tangential grinder

| Reference: | 163-ME08 | |

| Table dimensions: | 400x800 mm | |

| Longitudinal traverse (X-axis): | 850 mm | |

| Cross traverse (Y-axis): | 460 mm | |

| Automatic penetration: | Yes | |

| Grinding wheel dimensions: | Ø 355x50x127 mm | |

| Approx machine weight: | 3550 Kgs | |

| Floor ocupation: | 3350x1730x1930 mm | |

| Year: | 2019 | |

| Equipped with: | ||

| Control: | Chevalier | |

| Electromagnet: | 800x400 mm of fine pole | |

| Paper filter: | Yes |

Do you need more information about this second hand CHEVALIER FSG-1632AD tangential grinding machine?

Contact us and we will inform you without any commitment on this Chevalier tangential grinder. In addition, if you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

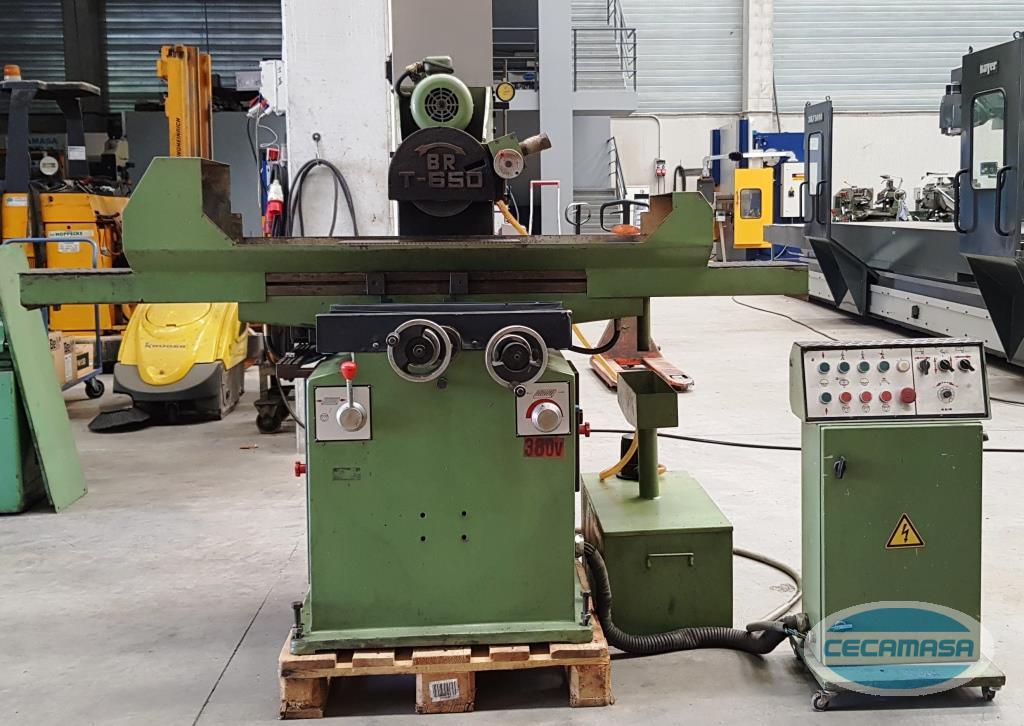

KAIR TBR-650 tangential

Information about the used KAIR TBR-650 tangential grinder

The Italian manufacturer of the brand KAIR is well-known for its agile, versatile and economical machines. That second-hand KAIR TBR-650 tangential grinder presents traverses that make it a very useful machine for the machining of small workpieces. The used KAIR grinding machine from our used machinery inventory is equipped with a manual magnetic chuck of the brand SELTER . This machine, ideal for any maintenance workshop, is in very good working conditions.

Technical characteristics of the used KAIR TBR-650 tangential grinder

| Reference: | 163-Y014 | |

| Table travel: | 740 mm | |

| Longitudinal traverse (X-axis): | 650 mm | |

| Cross traverse (Y-axis): | 300 mm | |

| Max height between the table and the wheel axis: | 390 mm | |

| Grinding wheel dimensions: | Ø 250x40 mm | |

| Grinding wheel speed: | 1750 rpm | |

| Grinding wheel power: | 2,28 kw | |

| Approximate weight: | 950 Kgs | |

| Machine dimensions: | 2000x1670x1800 mm | |

| Year: | 2000 | |

| Equipped with: | ||

| Selter magnetic chuck: | Manual - 505x205 mm |

Need more information about this second-hand KAIR TBR-650 tangential grinder?

Contact us and we will inform you without any commitment on this KAIR TBR-650 tangential grinder. If you wish, you can visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, CNC lathes, machining centers, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

GER CU 1000 CNC universal

Technical features of the used GER CU 1000 CNC universal grinder

| Reference: | 161-Y004 | |

| Distance between centers: | 1000 mm | |

| Centers' height: | 180 mm | |

| Max grinding diameter: | 450 mm | |

| X-axis travel: | 350 mm | |

| X-axis speed: | 0,01/1500 mm/min | |

| Z-axis travel: | 1300 mm | |

| Z-axis speed: | 0,01/1500 mm/min | |

| Grinding wheel dimensions: | Ø 500x80x203 mm | |

| Grinding wheel power: | 7.5 kw | |

| Approx machine weight: | 6500 Kgs | |

| Machine dimensions: | 4600x2400x2050 mm | |

| Year: | 2008 | |

| Equipped with: | ||

| Numerical Control: | FAGOR 8055 | |

| Head for internal grindings | ||

| Grinding wheel balancer | ||

| Paper filter with magnetic band | ||

| Several sets of wheels and drag drivers |

Need more information about this second-hand GER CU 1000 CNC universal grinder?

Contact us and we will inform you without any commitment on this GER CU 1000 CNC universal grinder . If you wish, you can visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, CNC lathes, machining centers, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

+ 34 935 730 225

+ 34 935 730 225