MEBUSA cnc press brake

Technical features of the second-hand MEBUSA SY 80/30 press brake

| Reference: | 130/Y022 | |

| Pressing force: | 80 Tn | |

| Working length: | 3190 mm | |

| Distance between frames: | 2660 mm | |

| Max travel: | 200 Mm | |

| Gap: | 400 Mm | |

| Backgauge travel: | 600 Mm | |

| Approach speed: | 100 Mm/sec | |

| Bending speed: | 10 Mm/sec | |

| Return speed: | 150 Mm/sec | |

| Engine power: | 10 CV | |

| Approx machine weight: | 8000 Kgs | |

| Machine dimensions: | 3435x2175x2885 mm | |

| Equipped with: | ||

| Numerical Control: | CYBELEC 70 (3 axes) | |

| Arms in the backgauge: | 5 |

Need more information about this used MEBUSA SY 80/30 hydraulic press brake?

Contact us and we will inform you without any commitment on this MEBUSA SY 80/30 hydraulic press brake. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

SORALUCE FS 8000

Information about the used SORALUCE FS 8000 traveling column milling machine

SORALUCE is a leading company in the manufacture of machine-tool in our country. It is part of Danobatgroup, one of the most relevant business groups on the European scene. SORALUCE has become synonymous with quality and technology. Not in vain this year 2020 SORALUCE has been awarded with the Ringier Technology Innovation Award. So it comes as no surprise that in our machinery park we always have milling machines of this prestigious brand.

Currently, we have a very special machine for sale: a second-hand SORALUCE FS 8000 traveling column milling machine. This used Soraluce milling machine has a longitudinal traverse of 8000mm, a vertical traverse of 3200 mm and a cross one of 1600 mm. Those traverses, along with its three heads, make this machine, a highly competitive milling machine.

This traveling column milling machine is equipped with an automatic head pick-up. The most remarkable head of this machine is its orthogonal head with an accuracy of one thousandth of a degree with HSK-63A spindle taper. It reaches a speed of 18,000 rpm and it can work 5 continuous axes. It is capable of performing mirror machining characteristic of the tooling sector. Although it can also work soft materials such as master paste or aluminum, carrying out a machining of the highest quality.

The second head is an automatic universal head with an accuracy of one thousandth of a degree capable of working at 6000 turns and with a power of 43 kW. It is ideal to perform heavy machining or wear.

The third head is an outlet type to carry out horizontal works. It also has a power of 43 kW which makes it an ideal head for drilling as required in tube sheets.

In addition to the head pick-up, this machine is equipped with different probes to center the pieces, a chip conveyor, 4 squares 3 meters high and a STOLLE plate of 10,000 × 2,500 mm.

The technical specifications of this machine, as well as its high performance, make this second-hand SORALUCE FS 8000 milling machine, in a traveling column milling machine ideal for machining heavy parts. It has multiple applications, either in the automotive sector, the railway sector, or even in the wind power sector since it can work parts such as bushings.

Technical features of the second-hand SORALUCE FS 8000 traveling column machine

Reference: 073-N250

X-axis traverse: 8.000 mm

Y-axis traverse: 1.600 mm

Z-axis traverse: 3.200 mm

Year of the machine: 2011

Milling head 1

Orthogonal head with high-speed spindle: Ultra high rotation speed of the head and elbow - continuous

Spindle taper: HSK-63A

C-axis pos: ± 180º

A-axis pos: ± 180º

Accuracy: 0.001º (360,000 pos)

Max speed: 18.000 rpm

Engine power: 25 kW

Milling head 2

Automatic head: universal

Spindle taper: ISO 50

Max rotation angle: nX360º

Accuracy: A and B axes 0.001º (360,000 pos)

Max speed: 6.000 rpm

Engine power: 43 kW

Milling head 3

Universal milling head: Direct outlet for horizontal millings

Spindle taper: ISO 50

Max speed: 20-5.000 rpm

Engine power: 43 kW

Rapid traverses (X, Y, Z): 25.000 mm/min

Equipped with:

Control: HEIDENHAIN iTNC 530

Radiofrequency hand-wheel: HEIDENHAIN HGB410

M&H 20.41 radiofrequency touch probe: for piece centering in ISO 50 spindle taper

M&H 20.41 radiofrequency touch probe: for piece centering in HSK63 spindle taper

Pick-up of heads: 3 positions

Static pneumatic tool changer: 12 magazines adapted to the table

Coolant system: of head oil

Preparation coolant system through the spindle Yes

Prepared for internal coolant supply through the spindle the 3 heads

Mobile platform for operator: with hydraulic height regulation

STOLLE plate: 10,000x2,500 mm

4 squares: 3,000x1,100 mm

Chip conveyor: Yes

Need more information about this second-hand SORALUCE FS 8000 milling machine?

Contact us and we will inform you without any commitment on this SORALUCE FS 8000 traveling column milling machine. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, cylinders, shears, press brakes, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

AWEA EP 4025 machining center

Information about the second-hand AWEA EP 4025 bridge machining center

The Taiwanese company AWEA Mechantronic Co., LTD, founded in 1986, manufactures all kinds of machining centers. East second-hand AWEA machining center, model EP4025 is practically new since its year of manufacture was 2015, but it was not set up at the customer's premises until mid-2016.

Highlight of this machine, the 2700 mm of the passage between uprights and its height of 1500 mm. These measures allow to put any type of piece, block, matrix, mold of great dimensions. In addition, this machine can support 15 tons of weight on the table.

As relevant extras, mention the 3 heads that the machine has: a direct outlet head, an extension piece and a 90º angular manual head. It is also equipped with a control HEIDENHAIN iTNC-530 and two chip conveyors: an auger type and another chain type to evacuate all the chip.

This second-hand AWEA machining center can be used in the die-making sector, in the mold sector and for machining large parts as it allows longitudinal machining of parts up to four meters.

Technical characteristics of the used AWEA EP 4025 machining center

| Reference: | 075-Y018 | |

| Table: | 4020 x 2400 mm | |

| Max weight on table: | 15.000 Kgs | |

| X-axis traverse: | 4020 mm | |

| Y-axis traverse: | 2500 mm | |

| Z-axis traverse: | 1000 mm | |

| Distance between columns: | 2700 mm | |

| Distance from upright to table (beam): | 1500 mm | |

| Direct outlet head: | 6000 rpm | |

| Extender: | 4000 rpm | |

| Angular manual head: | 90º - 3000 rpm (with internal coolant supply) | |

| Spindle taper: | BT 50 | |

| Rapid traverses (X, Y, Z): | 15 m/min | |

| Spindle motor: | 22 kW | |

| Year: | Dec 2015 - Set up in May 2016 | |

| Equipped with: | ||

| Control: | HEIDENHAIN iTNC-530 | |

| Electronic handwheel: | HR410 | |

| Internal chip extractor: | auger type | |

| Chip conveyor: | chain type | |

| Chip container: | Yes | |

| CE enclosure: | Yes |

Need more information about this second hand AWEA EP 4025 machining center?

Contact us and we will inform you without any commitment on this bridge machining center. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

BLECKEN cnc press brake

Information about the second-hand BLECKEN PPE-CNC 30160 hydraulic press brake

This second-hand press brake BLECKEN , model PPE-CNC 30160 has 3100 mm of bending length and 160 tons of power. It allows to work up to 8 mm in normal iron sheet and 4 mm in stainless steel in its entire bending length. If the sheet to be bent is of a shorter length, we will be able to bend a bigger thickness, depending on the die mouth and the punch. This second-hand press brake is of Turkish manufacture. It is a relatively modern machine since it was manufactured in 2008. It is worth highlighting its DELEM numerical control, one of the main manufacturers of numerical controls for folding machines that also, in this case, controls 6 axes. Likewise, this DELEM control allows a graphic preview of the part before bending in order to correct any type of error before carrying out the bending on the sheet. It is a 3D graphical pre-visualization and in color. In addition, this used press brake is equipped with a flexion compensation table, with a laser in the bending area and a light curtain in the back, thus complying with all CE regulations. It also has a 4-jaw die and has several punches of different sizes. Likewise, it also comes with 2 anvils. Being so well equipped and controlling so many axes, this machine allows any type of bending to be carried out on any sheet. From complicated bends to plywood, etc. This BLECKEN press brake is ideal for any metalwork, sheet metal, locksmith or even folding companies of any kind of complexity. It is in perfect working condition.

Technical features of the used BLECKEN PPE-CNC 30160 hydraulic press brake

| Reference: | 130/Y017 | |

| Pressing force: | 160 Tn | |

| Working length: | 3100 mm | |

| Distance between frames: | 2550 mm | |

| Max travel: | 180 Mm | |

| Table height: | 900 Mm | |

| Gap: | 400 Mm | |

| Distance from the table to the ram: | 429 Mm | |

| Backgauge X-R travel: | 500 / 200 Mm | |

| Approach speed: | 200 Mm/sec | |

| Bending speed: | 9 Mm/sec | |

| Return speed: | 80 Mm/sec | |

| Engine power: | 15 Kw | |

| Approx machine weight: | 9500 Kgs | |

| Machine dimensions: | 4250x2170x2800 mm | |

| Equipped with: | ||

| Numerical Control: | DELEM DA-66W (6 axes) | |

| Flexion compensation table: | Yes | |

| Multiple mouth dies: | 4 mouths Ø 60 mm | |

| Straight punch: | 3 point bending of 830 mm, several flanges (10 mm, 25 mm, 85 mm) and 2 anvils (105 mm) | |

| 4 arms in the backgauge: | different heights | |

| Front supports for metal sheet sliding: | 2 | |

| Safety light curtains in the rear part: | FIESSLER | |

| NUOVA laser: | CE protection |

Do you need more information about this second-hand BLECKEN PPE-CNC 30160 hydraulic press brake?

Contact us and we will inform you without any commitment on this BLECKEN PPE-CNC 30160 hydraulic press. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

NERVION 315 lathe

Information of the used NERVION 315 conventional lathe

NORDIC NERVION is a manufacturer in the Basque Country of universal or conventional lathes. The lathes NERVION have been characterized by being agile machines in terms of turning. They are designed for semi-heavy parts of different sizes depending on the lathe model. This NERVION 315 lathe is a second-hand machine with a distance between centers of 3000 mm and a max swing over bed of 630 mm. The lathe is located at our premises and it can perform any kind of lathe machining and carry out the maintenance of any type of company.

Technical features of the second-hand NERVION 315 universal lathe

| Reference: | 211-N242 | |

| Distance between centers: | 3000 mm | |

| Swing over bed: | 630 mm | |

| Swing over cross slide: | 400 mm | |

| Swing over bed without gap: | 850 mm | |

| Gap length: | 200 mm | |

| Quill diameter: | 74 mm | |

| Equipped with: | ||

| Chuck: | universal 3-jaws 315 mm diameter | |

| Sets of jaws: | 2 | |

| Turret: | Quick change | |

| Tool holders: | Yes | |

| Steady rest: | Yes |

Do you need more information about this second-hand conventional NERVION 315 lathe?

Contact us and we will inform you without any commitment on this NERVION 315 conventional lathe. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, CNC lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

Steady rests

Technical characteristics of used lathe steadies

| Ref. 280/V091: | Open steady | Ø Max 145 - Min 40 mm |

| Ref. 280/V182: | Open steady | Ø Max 145 - Min 45 mm |

Do you need more information about these second hand steadies?

Contact us and we will inform you without any commitment on these steadies. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

Klinsman press brake

Technical features of the used hydraulic KLINSMAN RPP 160/320 press brake

| Reference: | 130/RPP160-3200 | |

| Pressing force: | 160 Tn | |

| Working length: | 3200 mm | |

| Distance between frames: | 2700 mm | |

| Ram travel: | 150 mm | |

| Ram travel adjustment: | 105 mm | |

| Max distance between table and ram: | 410 mm | |

| Throat depth: | 320 mm | |

| Table width: | 240 mm | |

| Engine power: | 11 Kw | |

| Approx machine weight: | 9400 Kgs | |

| Machine dimensions: | 3500x1640x2700 mm | |

| Equipped with: | ||

| Multiple mouth dies | ||

| Punch | ||

| Backgauge: | digitalized | |

| Ram: | digitalized |

Do you need more information about this second hand KLINSMAN RPP 160/320 hydraulic press brake?

Contact us and we will inform you without any commitment on this KLINSMAN RPP 160/320 hydraulic press brake. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

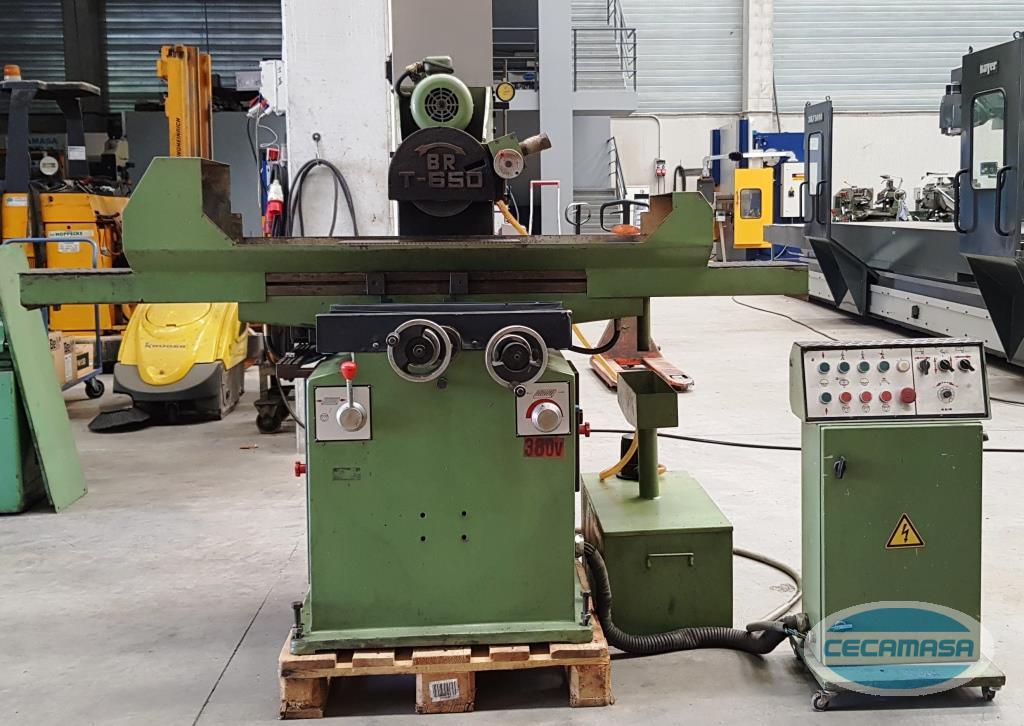

KAIR TBR-650 tangential

Information about the used KAIR TBR-650 tangential grinder

The Italian manufacturer of the brand KAIR is well-known for its agile, versatile and economical machines. That second-hand KAIR TBR-650 tangential grinder presents traverses that make it a very useful machine for the machining of small workpieces. The used KAIR grinding machine from our used machinery inventory is equipped with a manual magnetic chuck of the brand SELTER . This machine, ideal for any maintenance workshop, is in very good working conditions.

Technical characteristics of the used KAIR TBR-650 tangential grinder

| Reference: | 163-Y014 | |

| Table travel: | 740 mm | |

| Longitudinal traverse (X-axis): | 650 mm | |

| Cross traverse (Y-axis): | 300 mm | |

| Max height between the table and the wheel axis: | 390 mm | |

| Grinding wheel dimensions: | Ø 250x40 mm | |

| Grinding wheel speed: | 1750 rpm | |

| Grinding wheel power: | 2,28 kw | |

| Approximate weight: | 950 Kgs | |

| Machine dimensions: | 2000x1670x1800 mm | |

| Year: | 2000 | |

| Equipped with: | ||

| Selter magnetic chuck: | Manual - 505x205 mm |

Need more information about this second-hand KAIR TBR-650 tangential grinder?

Contact us and we will inform you without any commitment on this KAIR TBR-650 tangential grinder. If you wish, you can visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, CNC lathes, machining centers, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

Wide selection of bed type milling machines in CECAMASA

What is a bed type milling machine?

The Institute of Educational Technologies (ITE) defines bed type milling machine as a machine for machining by chip removal which can perform any kind of machining. Its main parts are: fixed bed, arm, upright or motorised bridge and table.

In the case of the bed type milling machine, the head moves up and down along the column. The table, however, only moves along the bed in its entire width.

In CECAMASA we have a wide selection of second hand bed type milling machines equipped with numercial control (cnc). Our inventory has prestigious brands such as ZAYER, SORALUCE, NICOLAS CORREA, LAGUN or ANAYAK.We are going to talk in further detail about the three bed type milling machines of our second-hand stock wich are in the state of immediate delivery.

Second-hand ZAYER 30 KF-5000 milling machine

In CECAMASA were experts in the brand Zayer. Zayer is a company based in Vitoria-Gasteiz with a long proven track record in the field of the machine tool of high performance. Zayer manufactures bed type milling machines, travelling column milling machines, gantry milling machines and milling centers. Zayer defines itself as "a company which guarantees machining solutions of high added value, technological and high quality".

Currently, we have in stock a ZAYER 30KF-5000 bed type milling machine. CECAMASA has carried out a thorough overhauling of that machine. Our team of highly qualified technicians has checked all the mechanic and electronic parts of this milling machine. They also have polised the covers, have replaced the polycarbonates and painted the machine.

The travels of this bed type milling machine are 4710 mm in the X-axis, 2013 mm in vertical and 1508 mm in cross. This exceptional machine presents a numerical control HEIDENHAIN TNC-426. It has an automatic head of 45 degrees with 0.001 positioning with twist of the two bodies simultaneously along with the spindle. The spindle reaches 3,000 rpm. In spite of being a bed type milling machine, it presents travels of a travelling column, but it does not require the foundation of a travelling column milling machine. Moreover, it has a chip conveyor. Find below a video where you can see the machine working under power:

Used SORALUCE TA-35 bed type milling machine

Along with Zayer, Soraluce is another leading brand in technology of milling. That comes as no surprise as Soraluce is part of one of the most relevant business group of machine tool in Europe: Danobatgroup. The Soraluce milling machines stand out for its realibility and high performance. It is a company wich works hard for being always at tech avant-garde and owns several patents which endorse its spirit of innovation.

Right now we have three Soraluce milling machines in our inventory: a Soraluce TA-20 bed type milling machine, a Soraluce TA-A20 bed type milling machine and one Soraluce TA-35 bed type milling machine. Although you can find detailed information about all of them in our website, in this occasion we would like to focus on the Soraluce TA-35 milling machine.

It is a bed type milling machine from 2009, which presents a longitudinal travel of 3500 mm, a cross travel of 1200 mm and a vertical one of 1250 mm. It has an automatic head of 2,5-2,5 degrees and the spindle reaches 3,000 rpm. It is a second-hand milling machine with some very attractive extras: tool changer of 20 units, internal and external coolant supply, 2 chip conveyors, paper filter, full enclosure and electronic hand-wheel, model Heidenhain HR 410. Find below a video of the machine and you will see for yourselves its capacities:

Used Nicolas Correa A30/40 bed type milling machine

In today's post apart from talking about Zayer and Soraluce, we cannot forget Nicolas Correa. Another great manufacturer of milling machines, which designs and produce entirely its machines in Spain. Nicolas Correa Sa company has been listed on the Madrid Stock Exchange for over 30 years and it has a wide commercial network and technical service at international level.

Currently we have at CECAMASA's premises a Nicolas Correa milling machine: the Nicolas Correa A30/40 milling machine, of which we are going to go through now.

We will begin by telling you that the series A30 of the brand NICOLAS CORREA is characterised by being a very robust and reliable machine. The A30/40 model presents 4000 mm of X-axis travel, 1500 mm Z-axis travel and 1250 in Y-axis travel. Those travels make this second hand milling machine ideal for sectors such as the one of the casting, the sector of metallic structures, machine shops and machining in general.

The bed type milling machine CORREA A30/40 has an automatic head and a central support in the table with T-slots. This support allows staking pieces in the side of the table without taking up space in the work table.

Our team of mechanics has pre-tensed the spindles, checked the proper functioning of the automatic head in the two bodies, checked the lubrication system, adjusted wedges to the fall of the ram, revised the guidelines, polished the telescopic covers and painted the machine.

More information

In this post we have talked about three models of bed type milling machines, but the stock of CECAMASA is much wider. We invite you to visit our website and know all our models of second-hand bed type milling machines available for sale. And if you want to know more about those second-hand machines, please do not hesitate to contact us. Drop us an email at cecamasa@cecamasa.com or call us on +34 935 730 225 and we will inform you in further detail.

LAGUN machining centers for sale at CECAMASA

Within the wide selection of used machinery CECAMASA, machining centers are always present. Along with milling machines - whether they are bed type milling machines, bridge milling machines or traveling column milling machines - and the numerical control lathes, the machining centers have a prominent position in our machine inventory. In today's post we are going to talk about the machining centers of the LAGUN brand. The word LAGUNmeans "friend" in Basque. Honoring this name, the machining centers of this Basque brand are emerging as the best ally to the machining processes of any company. Not in vain LAGUN machining centers are characterized by their great rigidity and by their compact as well as their ergonomic design.

The company LAGUN MACHINERY SL as such was established in 2005 in Vitoria (Álava). However, its origins go back to 1928 when at that time it was called "LADISLAO ARAMBURU". Almost a century of dedication to the design of machines for sectors such as aeronautics, the automotive sector, the die-cutting sector, just to name a few. Currently, the company LAGUN MACHINERY SL is part of the MAHER HOLDING group, a conglomerate of companies focused on the world of machine-tool which has set itself the main objective of offering simple solutions for an increasingly complex and demanding market.

CECAMASA has in its facilities located in the municipality of Parets del Vallès (Barcelona) two second-hand LAGUN L-1000 machining centers, which we will talk about below, as well as an L-1600 machining center (new machine) on display at the showroom.

Used LAGUN L-1000 vertical machining center (Year 2014)

This LAGUN L-1000 machining center is a modern machine, manufactured specifically in 2014, which is in excellent condition. The dimensions of the work table are 1070 × 510 mm and the maximum allowed weight are 700 kilos. Its travels are 1030 mm on the X axis, 530 mm on the Y axis and 540 mm on the Z axis. It also has a numerical control HEIDENHAIN iTNC 530 and it is equipped with a RANDOM 24-tool charger, chip conveyor and SCHENEIDER climate control equipment in the electrical cabinet. It is also prepared for a fourth axis. This second-hand machine stands out for its robustness and, above all, for its agility in axle translation, reaching 8,000 rpm. But as an image is worth a thousand words, we leave you with a video of the machine under power so that you can see for yourself the capabilities of this machining center:

Used LAGUN L-1000 Vertical machining center (Year 2011)

Convinced of the good results offered by this brand, in CECAMASA we have in inventory another LAGUN L-1000 vertical machining center. In this case it is a machine which dates from 2011 and with the same technical specifications described in the previous section. Then we also leave you with a video of the machine that is hosted in our YouTube channel, which I encourage you to subscribe to keep up to date with our news on used machinery.

LAGUN L-1600 machining center on display in our showroom (new machine)

If instead of second-hand machinery, you decide to invest in a new machine and you are looking for a larger machining center, you cannot miss the LAGUN L-1600 machining center that we have on display at the showroom of CECAMASA. In our post titled "CECAMASA exhibits a LAGUN L-1600 machining center in its facilities" you will find all the information related to this option. Emphasize that this is a machining center equipped with the latest version of numerical control from the prestigious brand HEIDENHAIN, the HEIDENHAIN TNC-640, and whose spindle reaches a speed of 8,000 rpm in its standard version, although the customer can choose to increase that speed to 10,000, 12,000 or even 15,000 rpm depending on their production needs. In fact, the model exhibited in the CECAMASA showroom reaches 10,000 rpm.

More information

If you want more details about these LAGUN machining centers, write us an email at cecamasa@cecamasa.com or call us at +34 935 730 225 and we will inform you in detail. If this pandemic has taken its toll on you economically, don't worry. At CECAMASA we can put you in contact with financing experts who will propose financial solutions adapted to your needs.

+ 34 935 730 225

+ 34 935 730 225