ANAYAK FV4 milling machine

Technical features of the used ANAYAK FV4 turret milling machine

| Reference: | 072-Y027 | |

| Table: | 1340x310 mm | |

| X-axis traverse: | 800 mm | |

| Y-axis traverse: | 400 mm | |

| Z-axis traverse: | 500 mm | |

| Spindle taper: | Spindle cone ISO 40 | |

| Max speed: | 50-2500 rpm | |

| Engine power: | 3 kW | |

| Equipped with: | ||

| FAGOR digital readouts: | 2 axes | |

| Steady rest: | yes | |

| Millholder post and several cones: | yes |

Do you need more information about this second hand ANAYAK FV4 milling machine?

Contact us and we will inform you without any commitment on this ANAYAK FV4 turret milling machine . If you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, bending machines, shears, folding machines, grinding machines, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

MEBUSA cnc press brake

Technical features of the second-hand MEBUSA SY 80/30 press brake

| Reference: | 130/Y022 | |

| Pressing force: | 80 Tn | |

| Working length: | 3190 mm | |

| Distance between frames: | 2660 mm | |

| Max travel: | 200 Mm | |

| Gap: | 400 Mm | |

| Backgauge travel: | 600 Mm | |

| Approach speed: | 100 Mm/sec | |

| Bending speed: | 10 Mm/sec | |

| Return speed: | 150 Mm/sec | |

| Engine power: | 10 CV | |

| Approx machine weight: | 8000 Kgs | |

| Machine dimensions: | 3435x2175x2885 mm | |

| Equipped with: | ||

| Numerical Control: | CYBELEC 70 (3 axes) | |

| Arms in the backgauge: | 5 |

Need more information about this used MEBUSA SY 80/30 hydraulic press brake?

Contact us and we will inform you without any commitment on this MEBUSA SY 80/30 hydraulic press brake. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

SORALUCE FS 8000

Information about the used SORALUCE FS 8000 traveling column milling machine

SORALUCE is a leading company in the manufacture of machine-tool in our country. It is part of Danobatgroup, one of the most relevant business groups on the European scene. SORALUCE has become synonymous with quality and technology. Not in vain this year 2020 SORALUCE has been awarded with the Ringier Technology Innovation Award. So it comes as no surprise that in our machinery park we always have milling machines of this prestigious brand.

Currently, we have a very special machine for sale: a second-hand SORALUCE FS 8000 traveling column milling machine. This used Soraluce milling machine has a longitudinal traverse of 8000mm, a vertical traverse of 3200 mm and a cross one of 1600 mm. Those traverses, along with its three heads, make this machine, a highly competitive milling machine.

This traveling column milling machine is equipped with an automatic head pick-up. The most remarkable head of this machine is its orthogonal head with an accuracy of one thousandth of a degree with HSK-63A spindle taper. It reaches a speed of 18,000 rpm and it can work 5 continuous axes. It is capable of performing mirror machining characteristic of the tooling sector. Although it can also work soft materials such as master paste or aluminum, carrying out a machining of the highest quality.

The second head is an automatic universal head with an accuracy of one thousandth of a degree capable of working at 6000 turns and with a power of 43 kW. It is ideal to perform heavy machining or wear.

The third head is an outlet type to carry out horizontal works. It also has a power of 43 kW which makes it an ideal head for drilling as required in tube sheets.

In addition to the head pick-up, this machine is equipped with different probes to center the pieces, a chip conveyor, 4 squares 3 meters high and a STOLLE plate of 10,000 × 2,500 mm.

The technical specifications of this machine, as well as its high performance, make this second-hand SORALUCE FS 8000 milling machine, in a traveling column milling machine ideal for machining heavy parts. It has multiple applications, either in the automotive sector, the railway sector, or even in the wind power sector since it can work parts such as bushings.

Technical features of the second-hand SORALUCE FS 8000 traveling column machine

Reference: 073-N250

X-axis traverse: 8.000 mm

Y-axis traverse: 1.600 mm

Z-axis traverse: 3.200 mm

Year of the machine: 2011

Milling head 1

Orthogonal head with high-speed spindle: Ultra high rotation speed of the head and elbow - continuous

Spindle taper: HSK-63A

C-axis pos: ± 180º

A-axis pos: ± 180º

Accuracy: 0.001º (360,000 pos)

Max speed: 18.000 rpm

Engine power: 25 kW

Milling head 2

Automatic head: universal

Spindle taper: ISO 50

Max rotation angle: nX360º

Accuracy: A and B axes 0.001º (360,000 pos)

Max speed: 6.000 rpm

Engine power: 43 kW

Milling head 3

Universal milling head: Direct outlet for horizontal millings

Spindle taper: ISO 50

Max speed: 20-5.000 rpm

Engine power: 43 kW

Rapid traverses (X, Y, Z): 25.000 mm/min

Equipped with:

Control: HEIDENHAIN iTNC 530

Radiofrequency hand-wheel: HEIDENHAIN HGB410

M&H 20.41 radiofrequency touch probe: for piece centering in ISO 50 spindle taper

M&H 20.41 radiofrequency touch probe: for piece centering in HSK63 spindle taper

Pick-up of heads: 3 positions

Static pneumatic tool changer: 12 magazines adapted to the table

Coolant system: of head oil

Preparation coolant system through the spindle Yes

Prepared for internal coolant supply through the spindle the 3 heads

Mobile platform for operator: with hydraulic height regulation

STOLLE plate: 10,000x2,500 mm

4 squares: 3,000x1,100 mm

Chip conveyor: Yes

Need more information about this second-hand SORALUCE FS 8000 milling machine?

Contact us and we will inform you without any commitment on this SORALUCE FS 8000 traveling column milling machine. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, cylinders, shears, press brakes, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

AWEA EP 4025 machining center

Information about the second-hand AWEA EP 4025 bridge machining center

The Taiwanese company AWEA Mechantronic Co., LTD, founded in 1986, manufactures all kinds of machining centers. East second-hand AWEA machining center, model EP4025 is practically new since its year of manufacture was 2015, but it was not set up at the customer's premises until mid-2016.

Highlight of this machine, the 2700 mm of the passage between uprights and its height of 1500 mm. These measures allow to put any type of piece, block, matrix, mold of great dimensions. In addition, this machine can support 15 tons of weight on the table.

As relevant extras, mention the 3 heads that the machine has: a direct outlet head, an extension piece and a 90º angular manual head. It is also equipped with a control HEIDENHAIN iTNC-530 and two chip conveyors: an auger type and another chain type to evacuate all the chip.

This second-hand AWEA machining center can be used in the die-making sector, in the mold sector and for machining large parts as it allows longitudinal machining of parts up to four meters.

Technical characteristics of the used AWEA EP 4025 machining center

| Reference: | 075-Y018 | |

| Table: | 4020 x 2400 mm | |

| Max weight on table: | 15.000 Kgs | |

| X-axis traverse: | 4020 mm | |

| Y-axis traverse: | 2500 mm | |

| Z-axis traverse: | 1000 mm | |

| Distance between columns: | 2700 mm | |

| Distance from upright to table (beam): | 1500 mm | |

| Direct outlet head: | 6000 rpm | |

| Extender: | 4000 rpm | |

| Angular manual head: | 90º - 3000 rpm (with internal coolant supply) | |

| Spindle taper: | BT 50 | |

| Rapid traverses (X, Y, Z): | 15 m/min | |

| Spindle motor: | 22 kW | |

| Year: | Dec 2015 - Set up in May 2016 | |

| Equipped with: | ||

| Control: | HEIDENHAIN iTNC-530 | |

| Electronic handwheel: | HR410 | |

| Internal chip extractor: | auger type | |

| Chip conveyor: | chain type | |

| Chip container: | Yes | |

| CE enclosure: | Yes |

Need more information about this second hand AWEA EP 4025 machining center?

Contact us and we will inform you without any commitment on this bridge machining center. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

BLECKEN cnc press brake

Information about the second-hand BLECKEN PPE-CNC 30160 hydraulic press brake

This second-hand press brake BLECKEN , model PPE-CNC 30160 has 3100 mm of bending length and 160 tons of power. It allows to work up to 8 mm in normal iron sheet and 4 mm in stainless steel in its entire bending length. If the sheet to be bent is of a shorter length, we will be able to bend a bigger thickness, depending on the die mouth and the punch. This second-hand press brake is of Turkish manufacture. It is a relatively modern machine since it was manufactured in 2008. It is worth highlighting its DELEM numerical control, one of the main manufacturers of numerical controls for folding machines that also, in this case, controls 6 axes. Likewise, this DELEM control allows a graphic preview of the part before bending in order to correct any type of error before carrying out the bending on the sheet. It is a 3D graphical pre-visualization and in color. In addition, this used press brake is equipped with a flexion compensation table, with a laser in the bending area and a light curtain in the back, thus complying with all CE regulations. It also has a 4-jaw die and has several punches of different sizes. Likewise, it also comes with 2 anvils. Being so well equipped and controlling so many axes, this machine allows any type of bending to be carried out on any sheet. From complicated bends to plywood, etc. This BLECKEN press brake is ideal for any metalwork, sheet metal, locksmith or even folding companies of any kind of complexity. It is in perfect working condition.

Technical features of the used BLECKEN PPE-CNC 30160 hydraulic press brake

| Reference: | 130/Y017 | |

| Pressing force: | 160 Tn | |

| Working length: | 3100 mm | |

| Distance between frames: | 2550 mm | |

| Max travel: | 180 Mm | |

| Table height: | 900 Mm | |

| Gap: | 400 Mm | |

| Distance from the table to the ram: | 429 Mm | |

| Backgauge X-R travel: | 500 / 200 Mm | |

| Approach speed: | 200 Mm/sec | |

| Bending speed: | 9 Mm/sec | |

| Return speed: | 80 Mm/sec | |

| Engine power: | 15 Kw | |

| Approx machine weight: | 9500 Kgs | |

| Machine dimensions: | 4250x2170x2800 mm | |

| Equipped with: | ||

| Numerical Control: | DELEM DA-66W (6 axes) | |

| Flexion compensation table: | Yes | |

| Multiple mouth dies: | 4 mouths Ø 60 mm | |

| Straight punch: | 3 point bending of 830 mm, several flanges (10 mm, 25 mm, 85 mm) and 2 anvils (105 mm) | |

| 4 arms in the backgauge: | different heights | |

| Front supports for metal sheet sliding: | 2 | |

| Safety light curtains in the rear part: | FIESSLER | |

| NUOVA laser: | CE protection |

Do you need more information about this second-hand BLECKEN PPE-CNC 30160 hydraulic press brake?

Contact us and we will inform you without any commitment on this BLECKEN PPE-CNC 30160 hydraulic press. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

NERVION 315 lathe

Information of the used NERVION 315 conventional lathe

NORDIC NERVION is a manufacturer in the Basque Country of universal or conventional lathes. The lathes NERVION have been characterized by being agile machines in terms of turning. They are designed for semi-heavy parts of different sizes depending on the lathe model. This NERVION 315 lathe is a second-hand machine with a distance between centers of 3000 mm and a max swing over bed of 630 mm. The lathe is located at our premises and it can perform any kind of lathe machining and carry out the maintenance of any type of company.

Technical features of the second-hand NERVION 315 universal lathe

| Reference: | 211-N242 | |

| Distance between centers: | 3000 mm | |

| Swing over bed: | 630 mm | |

| Swing over cross slide: | 400 mm | |

| Swing over bed without gap: | 850 mm | |

| Gap length: | 200 mm | |

| Quill diameter: | 74 mm | |

| Equipped with: | ||

| Chuck: | universal 3-jaws 315 mm diameter | |

| Sets of jaws: | 2 | |

| Turret: | Quick change | |

| Tool holders: | Yes | |

| Steady rest: | Yes |

Do you need more information about this second-hand conventional NERVION 315 lathe?

Contact us and we will inform you without any commitment on this NERVION 315 conventional lathe. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, CNC lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

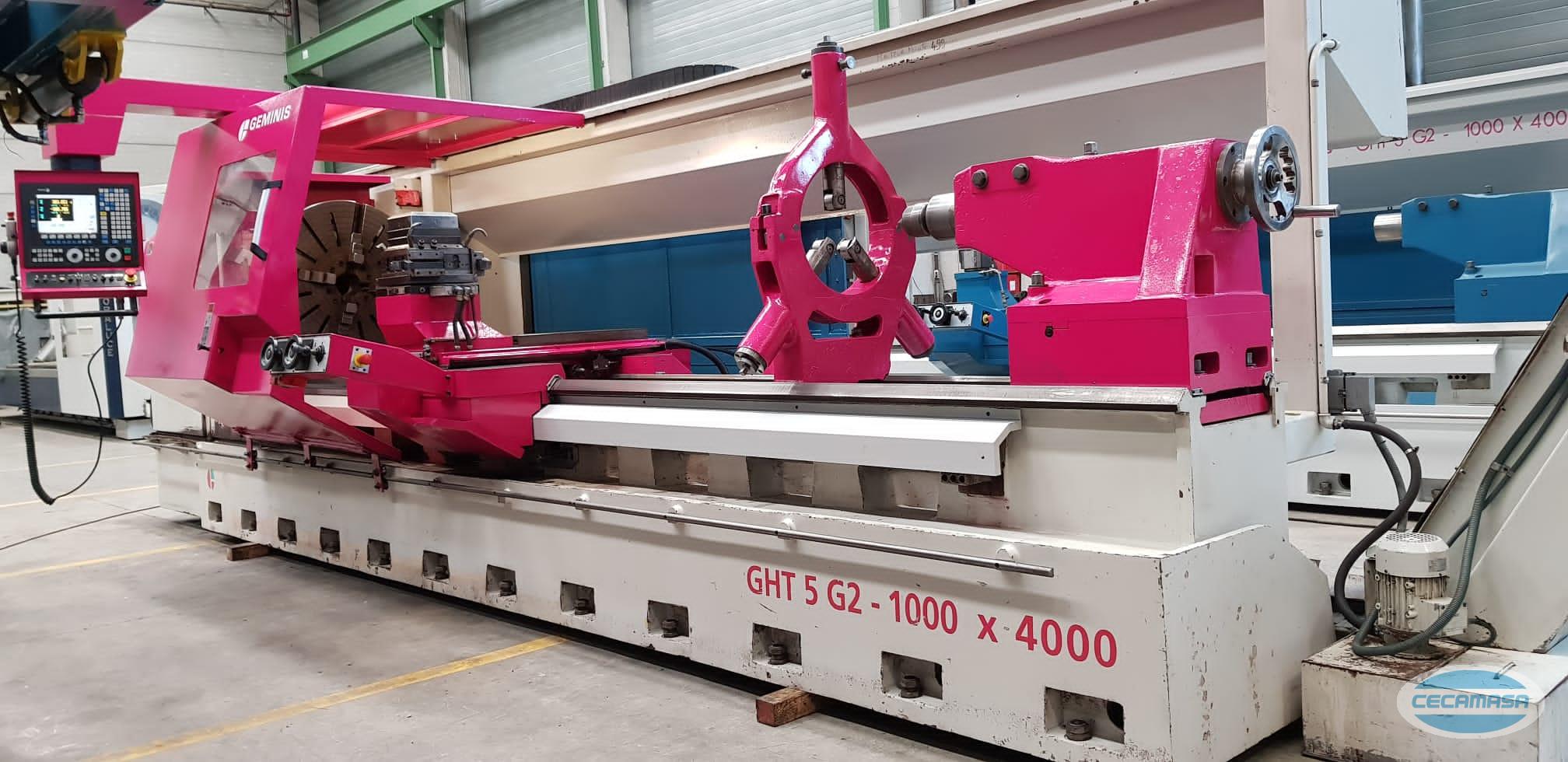

GEMINIS GHT5 G21000 × 4000 cnc lathe

Information of the used GEMINIS GHT5 G2 cnc lathe

GEMINIS is a company that is included within the group MAHER HOLDING, specialized in the sector of machine-tool . This business group, which also includes the manufacturer of milling machines and machining centers LAGUN, is one of the most important nationwide.

GEMINIS has always been known for being a manufacturer of heavy parallel lathe with numerical control. It is one of the most important brands in Europe and they have always stood out for being very reliable and prestigious lathes. CECAMASA, in addition to being a good collaborator of GEMINIS, has always been interested in having machines of this brand in stock. Our technicians know them very well and we overhaul them, leaving them in new quality condition.

In our facilities we currently have a second hand GEMINIS cnc lathe, GHT5 G2 1000X4000 model. This used cnc lathe is equipped with a boring support on the carriage. This large support allows the operator to drill with great precision and great depths. The lathe is also equipped with a control FAGOR 8055, a steady rest, a chip extractor, a TDG chuck with 4 independent jaws and a diameter of 900 mm. This second-hand cnc lathe is prepared to perform heavy parts, as GEMINIS lathes have always been characterized. This machine has good diameters and is suitable for any machining of rollers, tubular parts, etc. and for different sectors from maintenance to parts for wind power.

Technical features of the second hand GEMINIS GHT5 G2 cnc lathe

| Reference: | 218-Y008 | |

| Distance between centers: | 4.000 mm | |

| Max swing over bed: | 1,000 mm | |

| Swing over cross slide: | 680 mm | |

| Bed width: | 550 mm | |

| Spindle hole diameter: | 104 mm | |

| Quill diameter: | 140 mm | |

| Quill travel: | 300 mm | |

| Speed range: | 0-1.600 rpm | |

| Total power: | 28 Kw | |

| Year: | 2007 | |

| Equipped with: | ||

| Control: | FAGOR 8055 | |

| TdG manual chuck: | 4 independent jaws 900 mm diameter | |

| Boring support: | 100 mm diameter | |

| SAUTER automatic turret: | 4 stations 290 mm diameter | |

| Steady rest: | 3 points 430 mm diameter | |

| Cooling equipment: | Yes | |

| Lubrication: | Automatic | |

| Chip conveyor: | Yes | |

| Several tools: | Toolholder, points, jaws, bars, etc. |

Need more information about this second-hand GEMINIS GHT5 G2 cnc lathe?

Contact us and we will inform you without any commitment on this GEMINIS GHT5 G2 cnc lathe. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

DECKEL MAHO DMU 80 P hi-dyn machining center

Information about the used 5-axis continuous DECKEL MAHO DMU 80 P hi-dyn machining center

DECKEL MAHO machining centers are centers which have great popularity at European level. This German brand has been manufacturing both centers and lathes for many years. It is introduced in the railway, aeronautical sector, the mold sector, tooling and machining in general. DECKEL has always sold machines of German reliability and proven reputation.

This machining center DECKEL MAHO DMU 80 P hi-dyn specifically was bought from the company PORSCHE, the popular manufacturer of luxury cars. This machine comes from the R&D department that is intended for prototyping. For this reason this machine has not suffered a great workload. It is in perfect condition. We are talking about a 5-axis continuous technological production machine. In addition to having the X, Y, Z axes, it has an axis in the head (axis A) and another axis in the rotary table (axis C). It has an ISO 50 cone, which makes this machining center a heavy machine at 8,000 rpm. It is equipped with control HEIDENHAIN iTNC-530.

Furthermore, this high-performance machining center is equipped with an optical transmission probe from the prestigious Renishaw brand, a chip conveyor, internal coolant supply and it has a 120-tool magazine, which gives it a very wide machining versatility.

Technical features of the second-hand 5 axis DECKEL MAHO DMU 80 P hi-dyn machining center

| Reference: | 075-X026 | |

| Rotary table dimensions: | Ø 630 mm | |

| Maximum weight on table: | 600 kgs | |

| Spindle-table distance: | 180-680 mm | |

| X-axis traverse: | 800 mm | |

| Y-axis traverse: | 700 mm | |

| Z-axis traverse: | 600 mm | |

| A-axis: | + 45º -30º | |

| C-axis: | 360º | |

| Spindle taper: | ISO 50 DIN 69871 | |

| Speed range: | 20-8000 rpm | |

| Year: | 2003 | |

| Equipped with: | ||

| Control: | HEIDENHAIN iTNC 530 | |

| Electronic handwheel: | HEIDENHAIN HR-410 | |

| ATC tool changer: | 120 tools | |

| Internal cutting oil with paper filter: | 20 bar | |

| Temperature controller: | KNOLL | |

| Temperature compensator: | Yes | |

| Chip conveyor: | Yes | |

| Chip trolley: | Yes | |

| Smoke extractor: | Mist | |

| Workpiece measurement system: | Laser Blum | |

| Probe: | Renishaw OMP60 | |

| Software: | TNC REMO | |

| Ethernet: | Yes |

Need more information about this second-hand 5 axis DECKEL MAHO DMU 80 P hi-dyn machining center?

Contact us and we will inform you without any commitment on this DECKEL MAHO DMC 80 P hi-dyn machining center. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

Steady rests

Technical characteristics of used lathe steadies

| Ref. 280/V091: | Open steady | Ø Max 145 - Min 40 mm |

| Ref. 280/V182: | Open steady | Ø Max 145 - Min 45 mm |

Do you need more information about these second hand steadies?

Contact us and we will inform you without any commitment on these steadies. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

Klinsman press brake

Technical features of the used hydraulic KLINSMAN RPP 160/320 press brake

| Reference: | 130/RPP160-3200 | |

| Pressing force: | 160 Tn | |

| Working length: | 3200 mm | |

| Distance between frames: | 2700 mm | |

| Ram travel: | 150 mm | |

| Ram travel adjustment: | 105 mm | |

| Max distance between table and ram: | 410 mm | |

| Throat depth: | 320 mm | |

| Table width: | 240 mm | |

| Engine power: | 11 Kw | |

| Approx machine weight: | 9400 Kgs | |

| Machine dimensions: | 3500x1640x2700 mm | |

| Equipped with: | ||

| Multiple mouth dies | ||

| Punch | ||

| Backgauge: | digitalized | |

| Ram: | digitalized |

Do you need more information about this second hand KLINSMAN RPP 160/320 hydraulic press brake?

Contact us and we will inform you without any commitment on this KLINSMAN RPP 160/320 hydraulic press brake. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

+ 34 935 730 225

+ 34 935 730 225