FEXAC UM milling machine

Technical characteristics of the used FEXAC UM universal milling machine

| Reference: | 072-C013 | |

| Table: | 1300x300 mm | |

| Longitudinal traverse (X-axis): | 950 mm | |

| Cross traverse (Y-axis): | 275 mm | |

| Vertical traverse (Z-axis): | 500 mm | |

| Number of feedrates: | 12 | |

| Longitudinal and cross (min and max): | 11-500 mm/min | |

| Vertical (min and max): | 4,2-200 mm/min | |

| Longitudinal and transverse rapid traverse: | 2500 mm/min | |

| Vertical rapid traverse: | 1000 mm/min | |

| Power: | 4 CV | |

| Spindle taper: | Spindle cone ISO 40 | |

| Speed range: | 12, 30-1200 rpm | |

| Approx machine weight: | 2370 kgs | |

| Machine dimensions: | 1950x1380x1670 mm | |

| Equipped with: | ||

| Digitals: | MITUTOYO | |

| Head: | Universal |

Do you need more information about this second-hand FEXAC UM universal milling machine?

Contact us and we will inform you without any commitment on this universal milling machine. If you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, bending machines, shears, folding machines, grinding machines, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

FEXAC UM milling machine

Technical characteristics of the used FEXAC UM universal milling machine

| Reference: | 072-C011 | |

| Table: | 1300x300 mm | |

| Longitudinal traverse (X-axis): | 950 mm | |

| Cross traverse (Y-axis): | 275 mm | |

| Vertical traverse (Z-axis): | 500 mm | |

| Number of feedrates: | 12 | |

| Longitudinal and cross (min and max): | 11-500 mm/min | |

| Vertical (min and max): | 4,2-200 mm/min | |

| Longitudinal and transverse rapid traverse: | 2500 mm/min | |

| Vertical rapid traverse: | 1000 mm/min | |

| Power: | 4 CV | |

| Spindle taper: | Spindle cone ISO 40 | |

| Speed range: | 12, 30-1200 rpm | |

| Approx machine weight: | 2370 kgs | |

| Machine dimensions: | 1950x1380x1670 mm | |

| Equipped with: | ||

| Digitals: | FAGOR | |

| Head: | HURON |

Do you need more information about this second-hand FEXAC UM universal milling machine?

Contact us and we will inform you without any commitment on this universal milling machine. If you wish, you can also visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, conventional lathes, cnc lathes, bending machines, shears, folding machines, grinding machines, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

PINACHO S-90/225 lathe

Technical characteristics of the second-hand PINACHO S-90/225 universal lathe

| Reference: | 211-C006 | |

| Distance between centers: | 1650 mm | |

| Max swing over bed: | 450 mm | |

| Swing over carriage: | 410 mm | |

| Swing over cross slide: | 260 mm | |

| Swing over gap: | 650 mm | |

| Bed length: | 300 mm | |

| Spindle hole: | 52 mm | |

| Spindle Morse taper: | 4 | |

| Speeds: | 40-2200 rpm | |

| Main motor power: | 4 Kw | |

| Year: | 2001 | |

| Equipped with: | ||

| Turret: | Quick change | |

| Steady rest: | Yes | |

| Several sets of jaws: | Yes | |

| Several sets of turret holders: | Yes | |

| CE standards: | Yes |

Do you need more information about this used PINACHO S-90/225 universal lathe?

Contact us and we will inform you without any commitment on this PINACHO lathe. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, CNC lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

PINACHO S-90/310 lathe

Technical characteristics of the second-hand PINACHO S-90/310 universal lathe

| Reference: | 211-C005 | |

| Distance between centers: | 1625 mm | |

| Centers' height: | 310 mm | |

| Max swing over bed: | 620 mm | |

| Swing over cross slide: | 425 mm | |

| Swing over gap: | 880 mm | |

| Spindle hole diameter: | 80 mm | |

| Gap length: | 220 mm | |

| Spindle speeds: | 12, 30-1500 rpm | |

| Engine power: | 7.5 CV | |

| Approx machine weight: | 1700 kgs | |

| Machine dimensions: | 2795x1020x1330 mm | |

| Equipped with: | ||

| 3-jaw universal chuck: | Ø 315 mm with protection | |

| Turret: | Quick change |

Do you need more information about this used PINACHO S-90/310 universal lathe?

Contact us and we will inform you without any commitment on this PINACHO lathe. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, CNC lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

SORALUCE SP 6000

Technical characteristics of the second-hand SORALUCE SP 6000 traveling column milling machine

Reference: 073-B053

Table dimensions: 6000x1100 mm

X-axis traverse: 4500 mm (rack-pinion)

Y-axis traverse: 1200 mm

Z-axis traverse: 2000 mm

Automatic head: 2.5º-2.5º

Spindle taper: ISO 50

Speed range: 20-5000 rpm

Total power: 32 kW

YOM: 2007

Equipped with:

Control: HEIDENHAIN iTNC 530

Electronic hand-wheel: HEIDENHAIN HR-420

Extended head for milling at 90 degrees: 500 mm

2 front extension tables: 1500x1200x1000 mm

2 squares: 2250x800x1200 mm

Electrical cabinet: cooling supply

Do you need more information about this second-hand SORALUCE SP 6000 milling machine?

Contact us and we will inform you without any commitment on this traveling column milling machine. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: machining centers, cylinders, shears, press brakes, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

PINACHO L1-260 lathe

Technical characteristics of the second-hand PINACHO L-1/260 universal lathe

| Reference: | 211-C002 | |

| Distance between centers: | 1625 mm | |

| Max swing over bed: | 520 mm | |

| Bed length: | 350 mm | |

| Swing over longitudinal carriage: | 470 mm | |

| Swing over cross carriage: | 320 mm | |

| Swing in the gap: | 770 mm | |

| Spindle hole diameter: | 68 mm | |

| Main motor power: | 7.5 CV | |

| Equipped with: | ||

| 3-jaw universal chuck: | Ø 310 mm | |

| Turret: | Yes |

Do you need more information about this used PINACHO L-1/260 universal lathe?

Contact us and we will inform you without any commitment on this PINACHO lathe. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, CNC lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

workshop tools

Technical characteristics of the used workshop tools

| Ref 280/TMV01: | Plato divisor Ø 500 mm | |

| Ref 280/TMV02: | Plato divisor Ø 250 mm | |

| Ref 280/TMV08: | ANDREA TA-120 boring head | |

| Ref. 280/TMV03: | Hydraulic clamp. Mouth 150. Opening: 120. | |

| Ref. 280/TMV04: | Hydraulic clamp. Mouth 120. Opening: 110. | |

| Ref. 280/TMV05: | Hydraulic clamp. Mouth 120. Opening: 110. | |

| Ref. 280/TMV07: | Rotating and tilting manual clamp. Mouth 160. | |

| Ref. 280/TMV06: | SELTER magnet drill. | |

| Ref 280/TMV19: | Durómetro CENTAUR. | |

| Ref. 280/TMV12: | Foot molar. | |

| Ref. 280/TMV09: | WENZEL Granite Precision Marble 2000x1000x250mm | |

| Ref. 280/TM69: | Pneumatic marker by micro-percussion. Marked field: 120x100 mm. Year 2012 |

Do you need more information about these second-hand workshop tools?

Contact us and we will inform you without any commitment on these used workshop tools. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

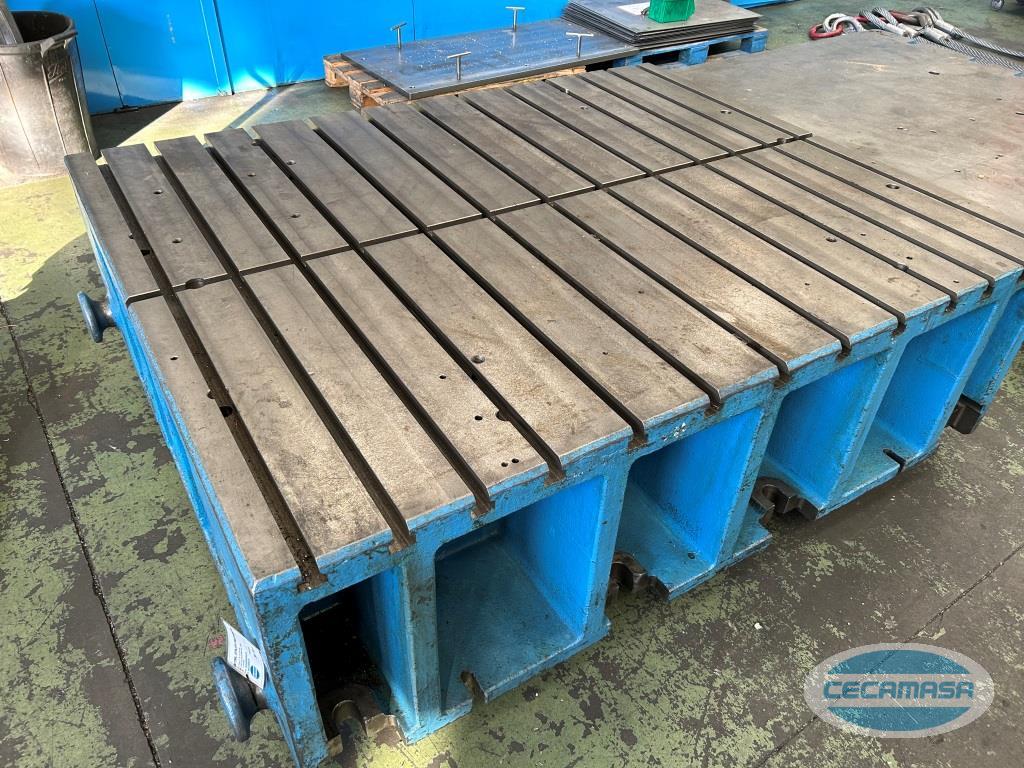

Tables, trestles and parallels

Technical characteristics of the tables, trestles and parallels used

| Ref. 280/TMV15: | Slot table with 15 T-slots. Dimensions: 1800x1500x560mm | |

| Ref. 280/MTV16: | 2 heavy-duty trestles with locking wheels. | |

| Ref. 280/TMV17: | 2 sets of 2 parallels 2200x500x600 mm unit | |

| Ref. 280/TMV18: | 2 sets of 2 parallels 2200x500x600mm unit | |

| Ref. 280/TMV20: | 4 foot table. Dimensions: 2800x1800x55 mm |

Do you need more information about these second-hand tables, trestles and parallels?

Contact us and we will inform you without any commitment on these used tables, easels and parallels. Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial equipment: machining centers, conventional lathes, CNC lathes, cylinders, shears, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

ONA KE 300 EDM

Technical characteristics of the second-hand ONA KE 300 wire EDM

| Reference: | 240-TM52 | |

| X axis: | 550 mm | |

| Y axis: | 300 mm | |

| Z axis: | 400 mm | |

| U axis: | 140 mm | |

| V axis: | 140 mm | |

| Max workpiece dimensions: | 1050x800x400 mm | |

| Max piece weight: | 3000 Kgs | |

| Max table speed: | 2000 mm/min | |

| Max conical cutting angle: | ±30º/95 mm | |

| Wire diameter: | 0.1-0.35 mm | |

| Type of wire spool: | DIN 100-125-160-200-DIN 355 (45 kg max) | |

| Min hole diameter: | 1.5 mm | |

| Max power: | 14 KVA | |

| Year: | 2005 | |

| Equipped with: | ||

| Control: | ONA |

Do you need more information about this second-hand ONA KE 300 wire EDM?

Contact us and we will inform you without any commitment on this used ONA edm . Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

ONA IN260 EDM

Technical characteristics of the second-hand ONA IN260 penetration EDM

| Reference: | 240-TM38 | |

| Tank dimensions: | 1000x600x375 mm | |

| Work table: | 650x400 mm | |

| Allowable weight on the table: | 1100 kgs | |

| Travels (X,Y,Z): | 500x300x200 mm | |

| Electrode weight: | 250 kgs | |

| Generator: | S2000-60 | |

| Power: | 9 Kw | |

| Equipped with: | ||

| POLY-SPARK |

Do you need more information about this second-hand ONA IN260 penetration EDM?

Contact us and we will inform you without any commitment on this used ONA edm . Please feel free to visit our facilities located in Parets del Vallés (Barcelona), where we have all kinds of new and used industrial machinery: Conventional milling machines, cnc milling machines, conventional lathes, cnc lathes, grinders, etc.

You can reach us via:

cecamasa@cecamasa.com

+34 935 730 225

+ 34 935 730 225

+ 34 935 730 225